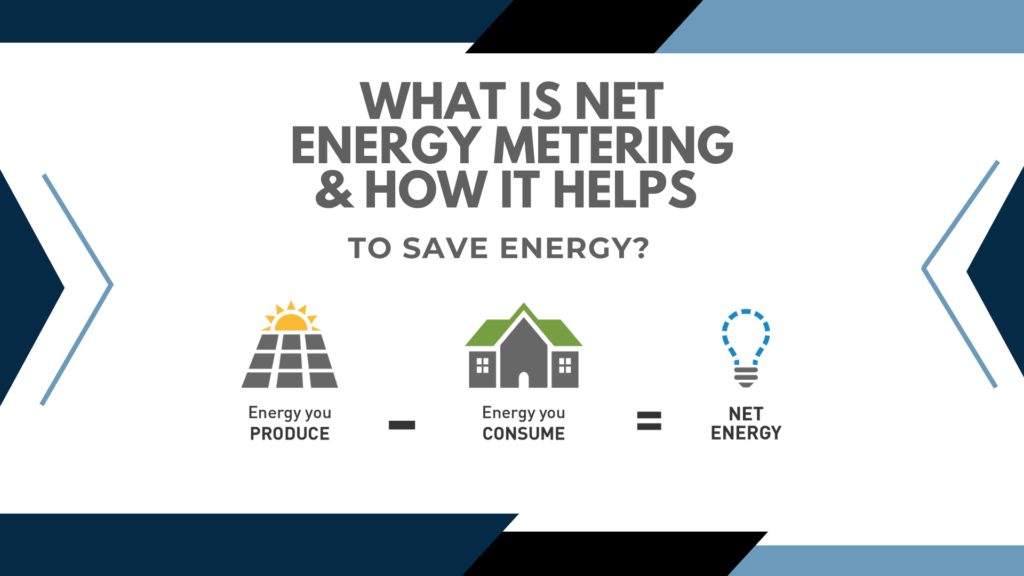

If you are generating more solar energy than you are consuming, the excess electricity is diverted to the grid and you are compensated for it by deducting the units you purchase from the grid. This simple concept is known as Net Metering.

As any top solar company will tell you, solar energy is gaining a lot of traction the world over and producers must be aware of Net Metering to make the most of their investment in solar power systems. VEMC is a leading Solar EPC Company based in Mumbai.

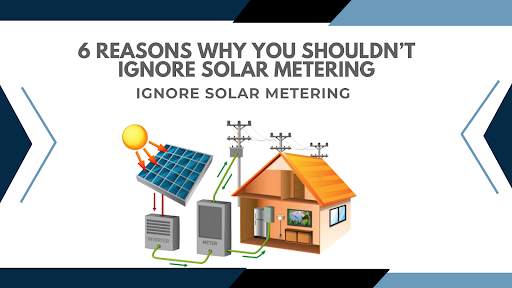

In This Blog, We Explain 6 Reasons Why You Simply Shouldn’t Ignore Solar Metering:

Lower Electricity Bill

With net metering, you only pay for the ‘net’ amount of electricity that you consume, that is, total electricity imported from the grid minus electricity exported from your solar power system. Besides, the extra electricity units can be used during those hours when sunlight isn’t enough such as at night.

Easy Installation With Fewer Components

There is no need to have a backup generator in net-metered solar power systems. The electricity grid itself acts as one. The lack of elaborate equipment and components makes the net-metered solar system an absolute winner. It also means that the initial costs of installing solar power systems come down significantly. For expert advice on this, get in touch with VEMC –– a top solar EPC company in its segment.

Lesser Environmental Impact

Solar energy is the most preferred unconventional source of energy, especially in terms of environmental impact. But when net metering is added to the equation, it further boosts the environmental benefits as it encourages users to switch to solar energy. Net metering, therefore, helps remove or reduce the reliance on conventional and polluting sources of energy like fossils.

Increased Financial Credit

Net metering provides owners of solar power systems an opportunity to generate revenue by selling the excess units to the grid. This acts as a financial motivator and helps owners increase their financial credibility by creating an asset that becomes a perpetual source of income.

Cost-Effective and Hassle-Free Maintenance

Net metering does away with components like batteries and generators –– the two that require the highest attention and maintenance. Thus, with net metering in place, your solar power systems become more cost-effective and have hassle-free maintenance.

Lesser Network Issues

With the increased number of consumers exporting their excess units to the electricity grid, the chances of blackouts and outages are successively reduced. Issues such as transmission line congestion can be significantly reduced thanks to net metering. An expert solar EPC company like VEMC will be able to tell you more about this.

Conclusion

If you want to install a solar system or have any queries regarding metering, do not hesitate to reach out to us. We will be happy to help you leverage net metering to make your place of work a shining example of the effectiveness of renewable energy. We are a leading Solar Power Company and can be reached at 022 43436655 or emailed at marketing@vemc.co.in.