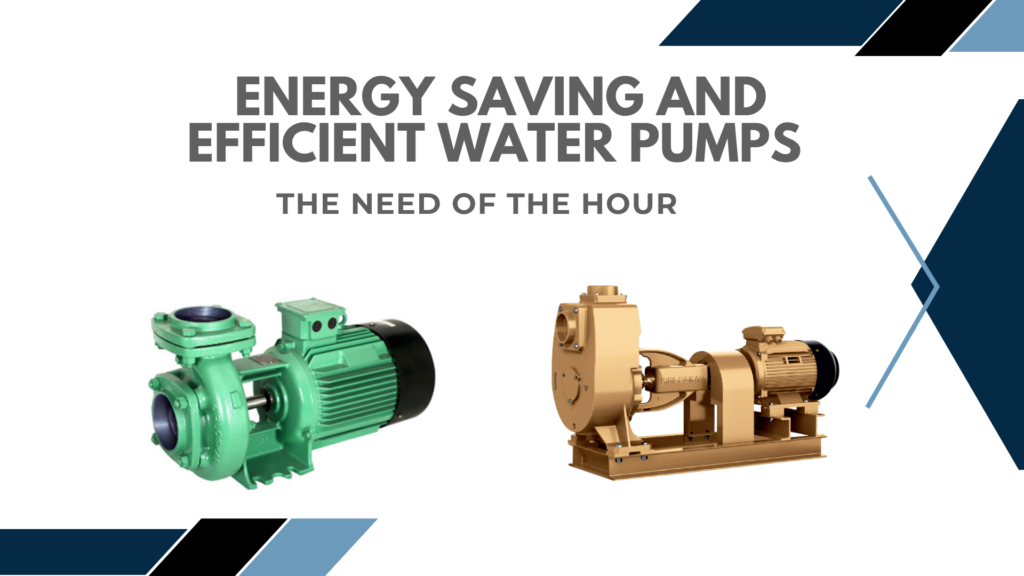

Advancements in technology have revolutionized a variety of industries and significant innovation has happened with the SP Coupled Pump Set with IE5 Motor. Industrial Water Pump Suppliers in Mumbai will likely say that this is a groundbreaking blend of a premier efficient motor and a special pump set that has exceptional power-saving functions and improved performance. Among industrial water pump dealers in Mumbai, you can rely on VEMC for the best pumps, maintaining sustainability with Government of India standards.

Here Are The Top 10 Industries Reaping The Benefits Of Such Cutting-Edge Advancements:

- HVAC Systems

Ventilation, heating, and air conditioning (HVAC) systems are vital to maintaining efficient and comfortable environments indoors, in commercial, residential, and industrial areas. The IE5 Motor coupled with the SP Pump has high efficiency and boosts the performance of HVAC systems, decreasing electricity consumption and resulting in eco-friendly actions.

- Water and Waste Water Management

Efficient management of water is critical for environmental conservation and sustainability. The SP Coupled Pump Set with IE5 Motor enables wastewater and water treatment plants to conduct operations with optimal energy efficiency. Consequently, operational costs are greatly reduced and a reliable water supply is assured.

- Manufacturing and Industrial Processes

As far as industrial water pumps in Mumbai go, you can rely on dealers like VEMC with expertise in the field. Industries that rely greatly on such pumps, like pharmaceuticals, chemical processing, and paper and pulp, achieve considerable energy savings with SP Pump Set use. Smooth operations, decreased downtime, and lower maintenance cost help improve profitability.

- Oil and Gas

The oil and gas industry requires top-class equipment to manage various processes efficiently. SP Coupled Pump Sets with IE5 Motors offer the required performance. Processes like refining, extraction, and transportation become more economical and energy-efficient.

- Building Services

Water pump dealers like VEMC have all the right solutions for the incorporation of SP Coupled Pump Sets with IE5 Motors in different building services, comprising fire-fighting systems and plumbing. The system’s proficiency translates into reduced energy bills for building owners, while the consistency and reliability of the water supply lead to the comfort of occupants. kirloskar Fire Fighting Pump Dealers highly recommend pumps like the SP Coupled Pump.

- Chemical and Petrochemical

In chemical/petrochemical industries, reliable and accurate pumping solutions are important for managing hazardous substances. SP Coupled Pump Sets are built in line with the latest technology and this ensures the safe handling of dangerous chemicals, promoting sustainability.

- Food and Beverage

Within the food and beverage industry, any Kirloskar fire pump dealer, such as the VEMC, will know that maintaining accuracy and hygiene in production processes is critical. SP Coupled Pump Sets with IE5 Motors offer dependable solutions for filling, pumping, and packaging applications, while helping maintain product integrity and sustainability.

- Mining and Quarrying

Mining operations involve dewatering processes that consume substantial energy. The IE5 Motor with the SP Pump brings high efficiency in challenging conditions, making it ideal for quarrying and mining mechanisms.

- Agriculture and Irrigation

In agriculture, proficient irrigation is crucial for maximizing the yield of crops and controlling water. The IE5 Motor, combined with the SP Pump, facilitates accurate irrigation, enabling proper water use, and resulting in sustainable farming.

- Renewable Energy

Industrial Water Pump Suppliers in Mumbai sell products with the environment in mind. Dealers like VEMC promote this as they deal in the SP Coupled Pump Set that complement wind and solar farms.

Conclusion

The SP Coupled Pump Set with IE5 Motor is a game-changer, and you can get your hands on it at VEMC, a top dealer in pumps with several years of expertise. Get in touch with us at +91 9819907445; we ensure reliability.