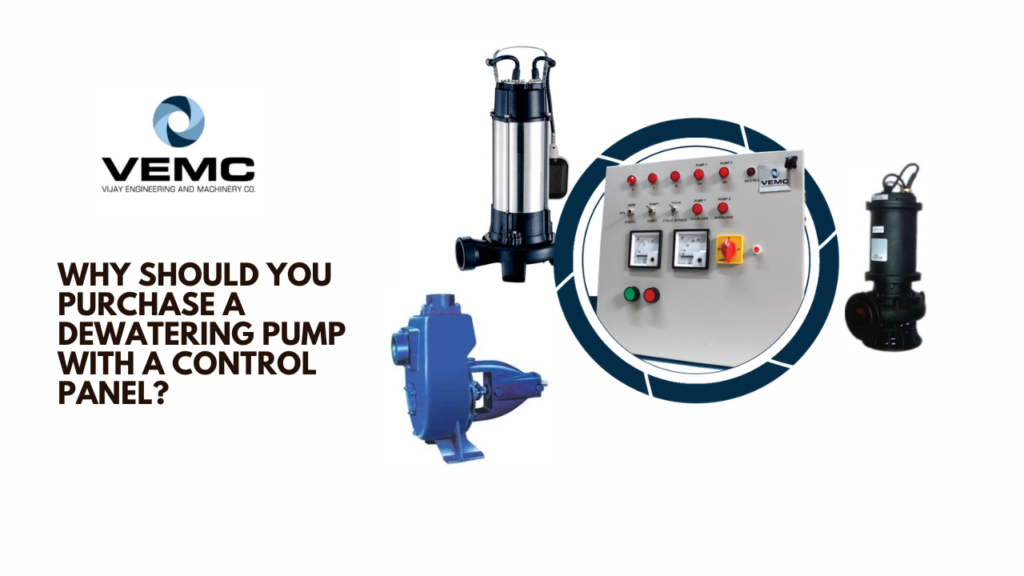

The control panel of a pump is used to automate the mechanics of motor control applications in water-based systems. It includes power components that determine how the pump motor works as well as several devices for operator control. There are also other sensors that help automate the machinery.

A majority of the time, pump control panels are for use outdoors. In these cases, they are enclosed by a protective layer that allows you to install the panel near a supply of water such as a well so that there is no risk of water damage to it. This is why it is very helpful to buy a dewatering pump with a control panel.

A pump control panel comes in various types and has different features. They can be pre-packaged, for heavy-duty or medium-level use. They can be single-phase, three-phase, duplex, or simplex control panels. They come in different current ratings and voltages. For a dewatering pump, you must choose a pump control panel that serves the purpose adequately.

Determine whether you want your dewatering pump to be used in harsh industrial conditions and the scale at which you plan to use it. These factors will help you select the right pump control panel for it.

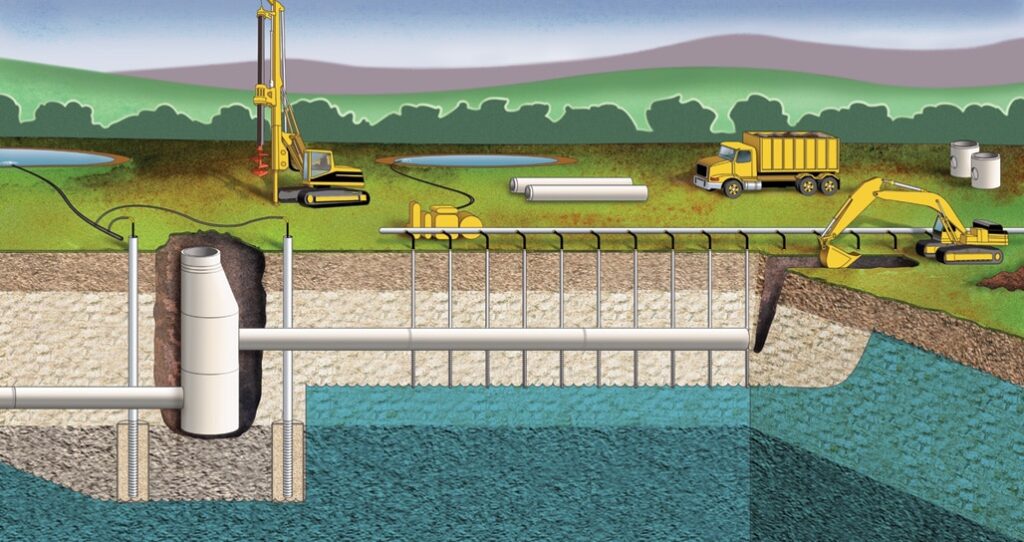

For dewatering purposes, you will probably have to use a pump that can drain waterlogged pits, floods, or entire floors in your industrial site. When you use it is also a significant factor. For example, draining floods in the monsoon will be a heavy-duty job, so it is important to take cognizance of this. The control panel you choose must support these operations properly by protecting the pump from water and other damage at all costs — its main function. It must be designed in a sturdy way that will enable it to hold up to the task.

Look for a control panel that is easy to install and has an entry point at the bottom for the times that the power supply is running underground

After you have identified your needs and observed the environment where you require the pump control panel, you will be ready to select a suitable control panel. Note that if a pre-packaged pump control panel will not meet your needs, you can always get a customized pump control panel tailored according to your preferences.For more information on industrial pumps, motors, and other equipment, please contact us at +91 98199 07445. We would be glad to help you find the best match for you based on your requirements. VEMC is a Kirloskar authorised dealer and provides complete project management services to its clients. We are ISO 9001:2015 certified and a pioneer in the field of electromechanical engineering products, allied equipment, and services.