Are you thinking about the purpose to use Industrial pumps and their functionalities?

Then let’ discuss in detail the industrial pumps!

Industrial pumps are used for various purposes in different enterprises across the world. The industrial pumps are usually the heavy-duty pumps that are best to move various items which include water, petroleum, chemicals, wastewater, oil, slurry, sludge, or food. There are multiple

types of pumps available in the market which are specially designed for industrial use.

Such huge numbers of enterprises use water pumps somehow. If they’re not used to supply water for manufacturing procedures, then they’re utilized in treating effluent and wastewater from plants. Local specialists apply strict guidelines to the treatment of effluents from industry to guarantee to protect the environment as well as the wellbeing of the community.

There is a wide scope of Pump Manufacturers and dealers In Navi Mumbai who are well-known to manufacture Kirloskar Pumps and Kirloskar Spare Parts. In any case, getting your water pumps fixed and reconditioned is simple.

Common types of Industrial Water Pumps available in the market :

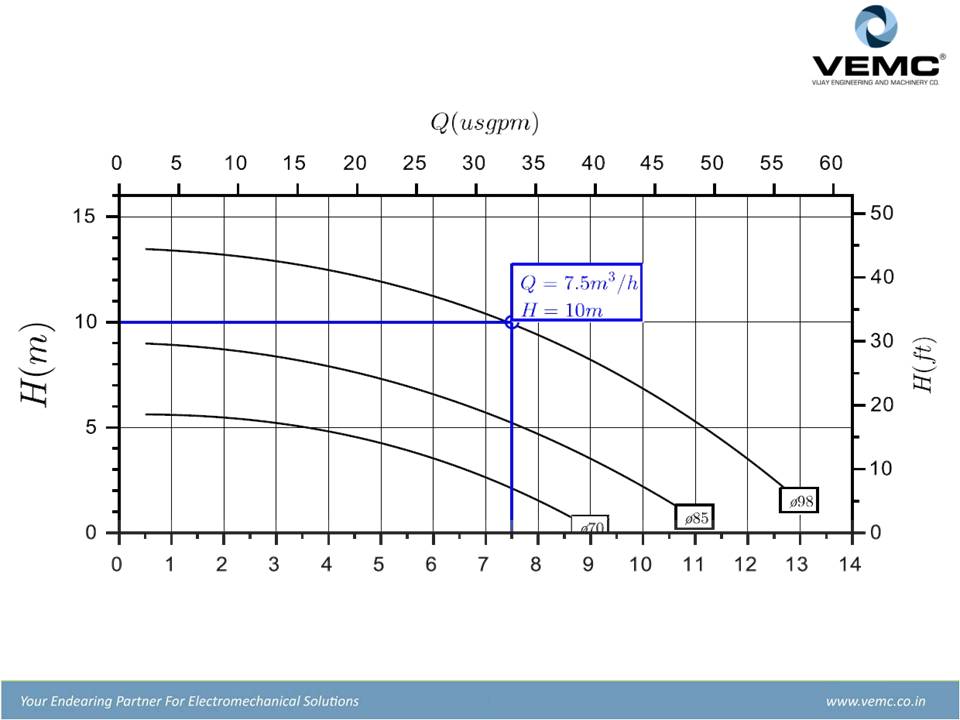

- Centrifugal pumps: A pivoting impeller draws water inside the pump, and then centrifugal activity pressurizes the water for release.

- Positive displacement pumps: One of these conveys a fixed volume of water from gulf to release with each stroke of the pump

Kirloskar pumps are popular among the industries due to their durability and high quality. The Water Pump Dealers In Navi Mumbai lays overwhelming pressure on the quality of the item and guarantees various quality checks with the goal that the clients get simply the best item. You can pick from prevalent classes like Domestic Monoblock Pumps, borewell submersible pumps, and get the top of the line items within their budget.

Functions

Industrial pumps are regularly utilized in the construction business. They are typically found in building locales where there is a need to evacuate overabundance water. These siphons are exceptionally helpful in zones that experience substantial downpours, which may cause flooding and where stale water can make disturbance work. With the assistance of water pumps, the amassed water can be immediately evacuated, so the construction task continues.

Types

Water pumps come in various kinds. They can be classified by how they work. As per Kirloskar Spare Parts Dealers In Navi Mumbai, pumping machines can be manual, electric, pressure-driven, or gas-fueled. Given how they move water, pumps can be ordered as divergent and positive removal pumps. The motive behind the use of all of them is to transfer water from one position to a new one.

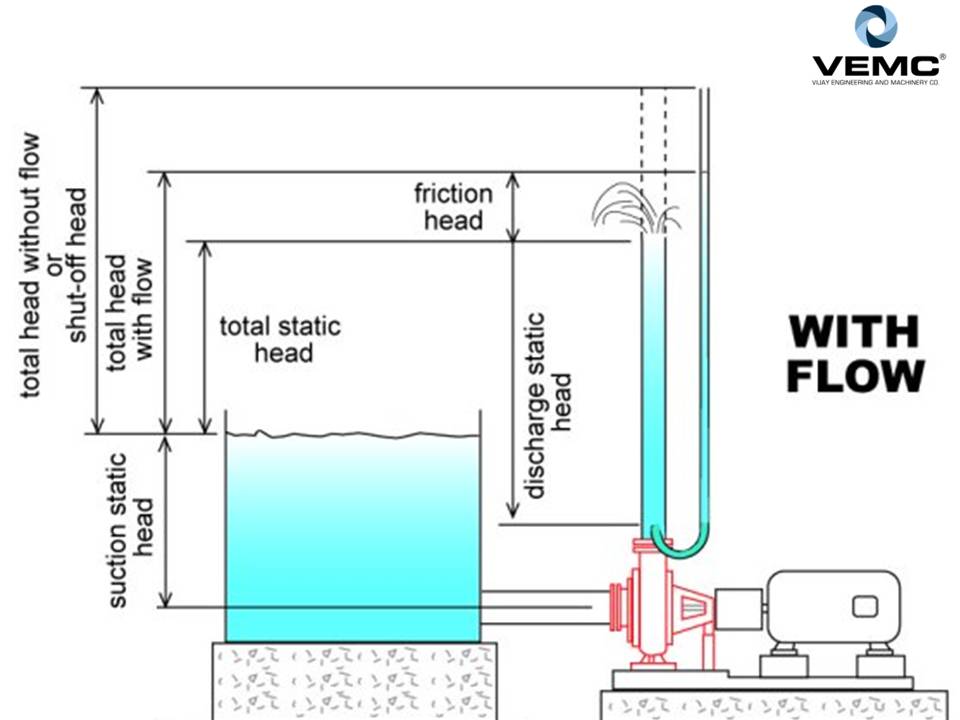

Regardless of whether you have purchased pumps from Water Pump Dealers in Navi Mumbai, this is something that you should do. The siphon execution fronts of the creators depend on clear water. The surmised imprint here is 65 F. This is except if the producers have expressed something different. You can be certain that they would not be adjusted for liquid thickness. In any event, when they have begun a pull, it might be remedied for specific gravity and viscosity.