Floods may cause immense damage to lives, properties, and infrastructure. With changing climate, the intensity and frequency of floods may increase and so, the relevance of effective measures for flood control must be considered seriously. Flood control requires sophisticated equipment and techniques and can help mitigate the adverse effects of increasing water levels with dewatering pumps. VEMC is one of the leading Industrial Water Pump Suppliers in Mumbai.

In This Article, We Will Share How Dewatering Pumps Act As Efficient Tools In Controlling Extensive Water Flow:

- Understanding Dewatering Pumps

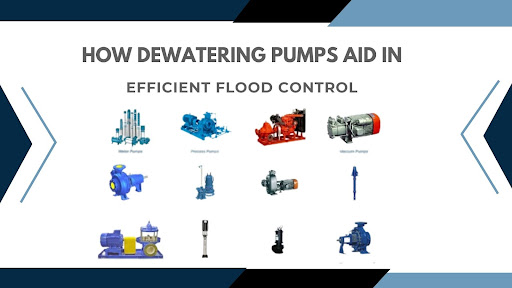

As any top industrial water pumps dealers in Mumbai like VEMC will explain, dewatering pumps are highly specialized devices that are designed to get rid of excess water from different areas, consequently preventing waterlogging and damage to machinery and lives in industrial units. They are available in a variety of configurations and sizes and cater to different requirements. Dewatering pumps are typically used in a range of locations like residential areas, construction sites, industrial plants, and commercial buildings, as well as infrastructure projects, where the accumulation of water poses a real threat. VEMC, with experience to back it, understands this and can provide industrial water pumps in Mumbai where flooding and waterlogging are perennial issues.

- Water Removal and Drainage

Efficient removal of water from waterlogged areas is one of the main functions of dewatering pumps. Dewatering pumps speedily extract water, lowering water levels and mitigating damage. Such actions are especially vital in low-lying areas. In such places, water is prone to rapidly accumulate and result in significant harm. You can be sure that Water Pump Dealers like VEMC, with their foresight, can provide preventive measures and solutions.

- Managing Groundwater Levels

Problems that worsen flooding in times of heavy rainfall are increasing groundwater levels. Dewatering pumps, such as any Kirloskar pumps distributors, are instrumental in the management of groundwater levels. Pumps effectively drain excess water, reducing any risk of flooding. This technique efficiently maintains soil stability and prevents any damage to infrastructure foundations.

- Temporary Water Diversion

In circumstances where floodwaters approach crucial areas, dewatering pumps can be used for the temporary diversion of water. Pumps help in minimizing damage and make time available for emergency response actions, by the redirection of water from vulnerable areas like residences and vital infrastructure.

- Flooded Basements and Buildings

Expert industrial water pump suppliers in Mumbai, like VEMC, know that during floods, basements and buildings are regularly at high risk of infiltration of water. Dewatering pumps get rid of water from buildings and flooded basements, preventing any mold growth and structural harm. Consequently, the process of restoration is aided when the water recedes.

- Construction and Infrastructure Projects

While working in locations that have a high water table, dewatering pumps prove indispensable in infrastructure and construction projects. VEMC, highly recommended industrial water pumps dealers in Mumbai, understand that pumps maintain dry construction sites, and facilitate safe working conditions. Pumps are also used in excavations for preventing seepage of water into work sites.

- Emergency Response and Preparedness

During natural disasters like floods, having efficient dewatering pumps ready is vital for effective responses. Such pumps are rapidly deployed to lessen the effects of flooding.

Conclusion

In the realm of disaster management, flood control is an important aspect, and the challenges it poses require reliable and efficient solutions. Especially in regions prone to flooding, industrial water pumps in Mumbai are a must. If you would like more information on dewatering pumps, don’t hesitate to contact us at +91 9819907445. We are the top Industrial Water Pumps Dealers in Mumbai with more than 70 years of expertise in dewatering solutions.