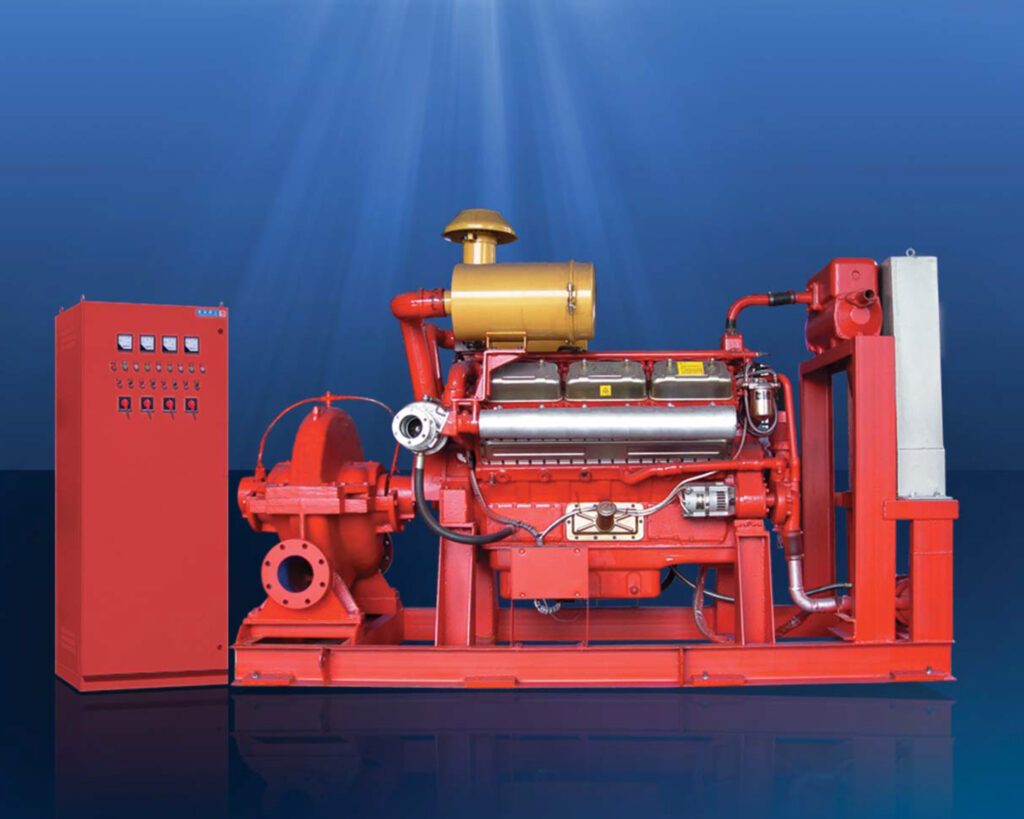

It is important that your fire pump is reliable, performs to its best levels and has a short response time to a breakout. Prior testing of the fire-fighting pumps is therefore crucial. VEMC is a leading Kirloskar fire pump dealer based in Mumbai, and in this blog, we take you through the importance and procedures of testing your fire-fighting pumps.

Legal requirements for regular fire pump testing

In India, fire safety is mandated at various levels of governance. The National Building Code (NBC) makes a provision for fire safety through pump installation and testing in section 4. Likewise, many states have their fire safety laws which provide detailed requirements for fire safety in buildings. Even at the municipal level, fire safety bylaws provide for fire pump testing intervals, standards and compliance checks.

Importance of fire pump testing

Fire pump testing is important to ensure preparedness in times of fire emergency. It can make the difference between life and death. So here’s why testing your fire pumps is necessary:

- Checking reliability: With regular fire pump testing, you can ensure the highest levels of reliability. Check for leaks, malfunctions, or any mechanical issues that can affect the pump’s performance regularly.

- Performance testing: Just having a functional fire pump is not enough. Your pump should be able to deliver an adequate amount of pressure and flow rate at the time of a fire emergency.

- Response time: Time is of critical importance in fire emergencies. How quickly your pump responds to a breakout could be decisive in preventing damage to property and loss of lives.

- Preventive maintenance: Regular testing and preventive maintenance of your fire pumps can help unearth mechanical issues or problems that can eventually cause malfunction when you need them to work the most.

- Compliance purposes: Laws across the world codify fire pump testing as an important fire safety measure. It is thus also important for building owners to carry out regular testing to meet compliance standards and avoid penalties.

Steps of testing your fire fighting pumps

- Preparation: Gather the pump manual and other documents, and inform all the stakeholders about the upcoming testing to minimise disruption of operations.

- Visual inspection: Visually check the pump and its surroundings for any indications of a failure. Check the valves, gauges and controls and ensure they’re in good working condition.

- Electrical and control system check: Make sure all electrical circuits, switches and panels are working.

- Suction piping inspection: Check the suction piping for any leaks, blockages or corrosion, and make sure it is correctly aligned.

- Flow and pressure testing: Use a flow meter to check the rate and pressure offered by the pump at various points.

- Operation testing: Run the pump, listen in for any unusual noise or vibration, and check its performance over a specified duration.

- Shut down and inspect: Shut the pump down and check for any post-testing issues.

- Documentation and reporting: Finally, record and document all the parameters tested. Prepare a detailed report including recommendations for the future.

For more on fire pump testing, call us on 022 43436655 or email us at marketing@vemc.co.in. We at VEMC are the leading Kirloskar fire pump dealer based in Mumbai.