When it comes to industrial water pump dealers in Mumbai, VEMC is one name that stands out. This is thanks to our years and years of rich experience in dealing with clients across industries. But experience aside, VEMC has also been flexible enough to reinvent itself and meet new challenges effectively. The best part however, is its ability to understand clients’ needs and establish long-term trustworthy business relationships with them.

We Give You Four Strong Reasons That Should Make Vemc Your Pump Supplier Of Choice.

Years of experience

VEMC has humble origins. It was established in the year 1948 in Mumbai, with a vision to offer reliable and endearing electromechanical solutions. During the 1950s it joined hands with Kirloskar Brothers Ltd. for selling Peter fielding engines. As of date, it has gathered over 70 years of experience in electromechanical engineering products, allied equipment, and services. VEMC’s clients include hotels, universities, hospitals and municipalities. Over the years, it has trained its human resources and created a robust talent pool to meet the challenges of the dynamic technology landscape and provide the highest quality of service. Today, the company has evolved from being a pump dealership to a full-fledged solutions provider.

Gets you the right pump for the job

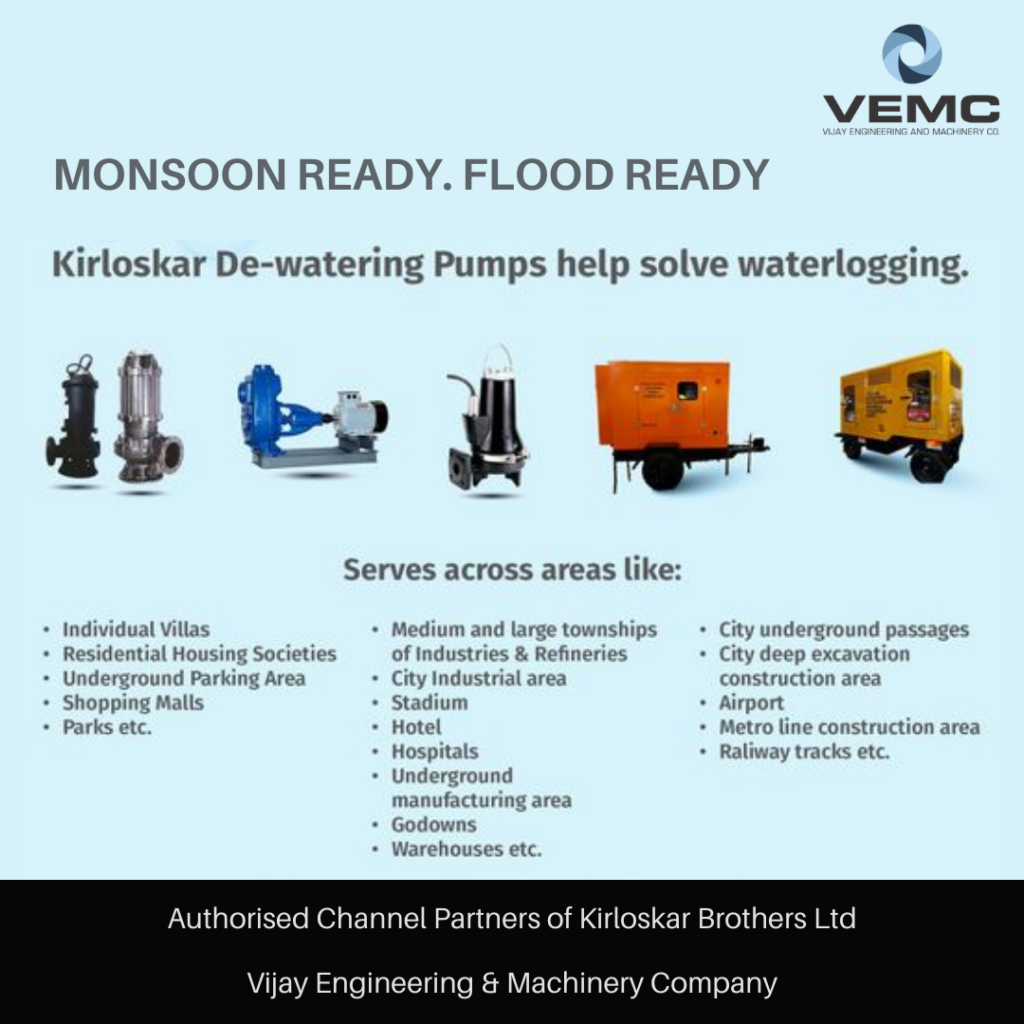

VEMC believes in forming strong bonds with its clients and understanding their business thoroughly. Whether it is for dewatering the streets or displacing water from a construction site, VEMC has a solution for every challenge. This availability of vast options coupled with its rich experience in pumping makes VEMC the most obvious choice for getting you the right pump for your needs every single time.

Clients can count on VEMCs service

As mentioned already, VEMC has seamlessly evolved itself from a pump dealership to a full-fledged service provider of choice. Their service begins as soon as a client gets in touch with them for a pumping solution. What follows is a fully planned and executed end-to-end project management service that installs the pumps and gets them running. Besides, VEMC also provides repair, restoration, and maintenance services anywhere across India. This makes the company the most reliable partner in the client’s fluid management journey. VEMC also offers energy audit services for pumps that help minimize energy wastage and improve clients’ operational efficiency.

Your success is our number 1 goal

Finally, VEMC believes in business partnership rather than salesmanship. Our business approach is the most crucial strategic decision for us. Our goal is not just to sell more pumps to clients, but helping them meet their business goals and partner with them along their journey. This unique approach of doing business makes VEMC stand out as one of the leading industrial water pump suppliers in Mumbai.

If you are looking for industrial water pumps in Mumbai, feel free to give us a call on 022 43436655 or email us at marketing@vemc.co.in. We are the leading Kirloskar pump dealers and take pride in being the best pump service providers out there.