Air compressors are one of the most valued pieces of equipment across industries for their incredible ability to generate power. These are used in operations like air conditioning, pneumatic tools, healthcare, food processing, sandblasting, demolition and painting. VEMC is one of the leading ELGi air compressor dealers in Mumbai, and in this blog, we talk about how air compressors are used in different sectors of the economy.

Powering pneumatic tools

Air compressors are used to power pneumatic tools like impact wrenches, air nails and staplers, air sanders and grinders, spray guns, air drills, and air hammers and chisels. These find applications in automotive repair, painting, carpentry, construction and metal-working. Large pneumatic tools such as Jackhammers are also used in the demolition of concrete, asphalt etc.

Sandblasting

With air compressors, abrasive materials like sand are pumped at high velocities against rough surfaces to make them smooth. This principle is also used to polish surfaces, remove old paint or rust, and prepare the surface for a new coat.

Painting

Air compressors are widely used in the automotive sector to spray-paint vehicles. Several variants of sprayers such as conventional, airless and High Volume Low Pressure (HVLP) sprayers are powered by air compressors depending upon the requirement of the operations. These sprayers are also used in industrial, domestic and commercial settings. Spray-painting using air compressors offers several benefits such as consistency, efficiency, versatility and high-quality finish.

Assembly lines

Thanks to the precision, reliability, speed and efficiency that air compressors offer, they are also used in assembly lines for several tasks. These include handling and positioning equipment, cleaning and maintenance, and automation and control systems.

Healthcare

In healthcare and medical operations, air compressors play a crucial role in many operations. These include supplying oxygen, generating vacuum systems for devices like catheters, powering ventilators, nebulisers, dental equipment, surgical tools, laboratory equipment, orthopaedic tools and dialysis equipment.

Mining

In the mining sector, air compressors provide support for several operations like blasting, powering rock drills, ventilation and cooling, powering conveyors, hosts and winches, operating pneumatic dewatering pumps and slurry pumps and core drilling.

Food processing

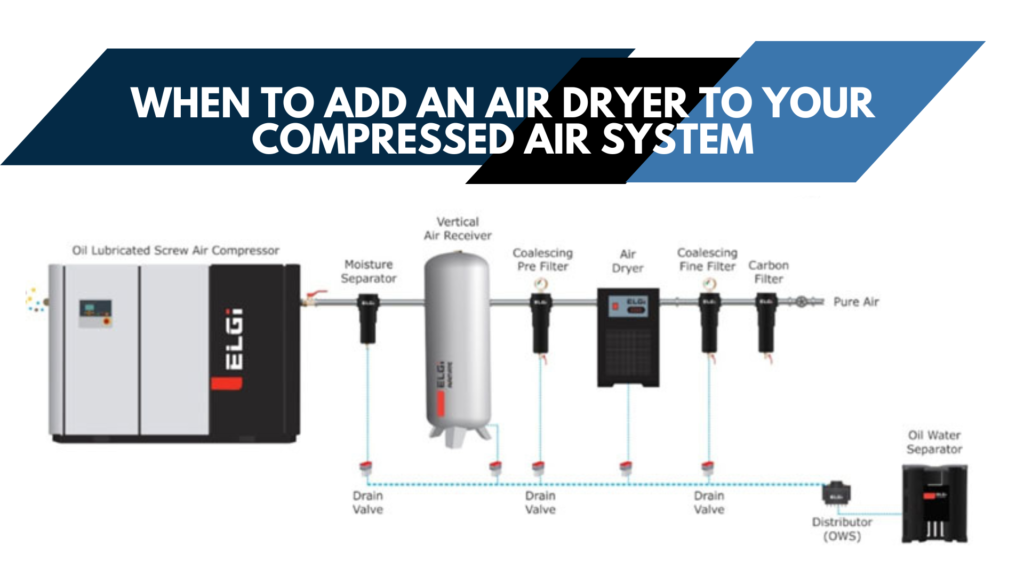

In the food processing industry, air compressors power conveyors, packaging machines, cleaning and sanitation, automatic sorting and packaging, and cooling and refrigeration. However, the quality of compressed air in the food processing industry is of critical importance to prevent spoilage by microbes or moisture.

Advancements in air compressor technology

As air compressor technology has improved and innovation has played its part, several advancements have been witnessed over the years. These include the use of Variable Speed Drives (VSDs), energy-efficient compression, smart control systems, heat recovery and predictive maintenance. Air compressors are also becoming increasingly lightweight and portable, oil-free, quieter and environmentally compliant.

For more about air compressors, feel free to get in touch with VEMC by calling on 022 43436655 or emailing us at marketing@vemc.co.in. We are one of the leading ELGi air compressor dealers in Mumbai.