Founded in the year 1948, Vijay Engineering and Machinery Company (VEMC) is one of the leaders in the electromechanical industry. Offering its wide range of products pertaining to Kirloskar Submersible Pumps, Horizontal split casing pumps, Multi stage horizontal pumps, and Mody pumps, to name a few. The establishment’s clientele list is Reliance Industries Limited, Aditya Birla group, Nilkamal, Eureka Forbes, Godrej and list includes myriad of other names.

Services that the company tenders include Installation and commissioning of Kirloskar pump-sets, all over India; On-site customer needs attended to, during and after warranty period and overhauling services for several pump-sets.

Fire fighting water pumps are integral components of any contemporary construction project, and VEMC plays a pivotal role in this essential domain. The following are some of the vital fire fighting solutions offered by the company:

Sprinkler Systems: VEMC provides advanced sprinkler systems that are crucial in fire suppression and protection. These systems are designed to automatically release water in the event of a fire, helping to control and extinguish flames, safeguarding lives and property.

Fire Hydrants: Fire hydrants are essential for providing access to a water supply for firefighters. VEMC ensures that buildings and facilities are equipped with reliable fire hydrants that meet safety standards.

Fire Pumps: VEMC offers an array of fire pumps designed to deliver water at high pressure for fire suppression. These pumps are a critical component of any fire protection system.

The establishment renders different fire fighting solutions. Fire fighting water pumps are playing the role of a savior these days. Without them, no building’s construction is said to be complete. Sprinkler system, fire hydrant and fire pumps, just to name a few are the ones with utmost importance in buildings and giant malls.

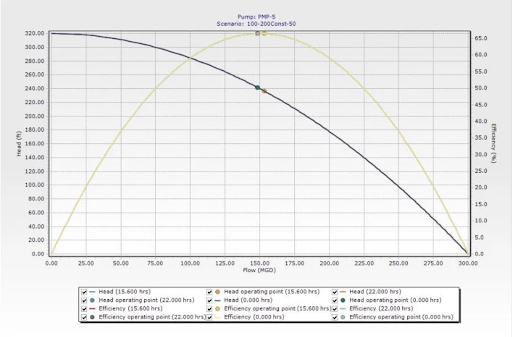

As a centrifugal pump distributor, VEMC supplies multistage centrifugal pumps, which are renowned for their efficiency and reliability. These pumps are utilized in various applications where the movement of liquids under high pressure is required.

The company is a centrifugal pump distributor and furnishes multistage centrifugal pumps. In addition, it offers fire fighting pump set that includes FM Approved UL Listed Fire Fighting Set, Multi Stage Multi Outlet (MSMO) pumps and many more. Multistage pumps are of two orientations, horizontal and vertical inline multistage pump.