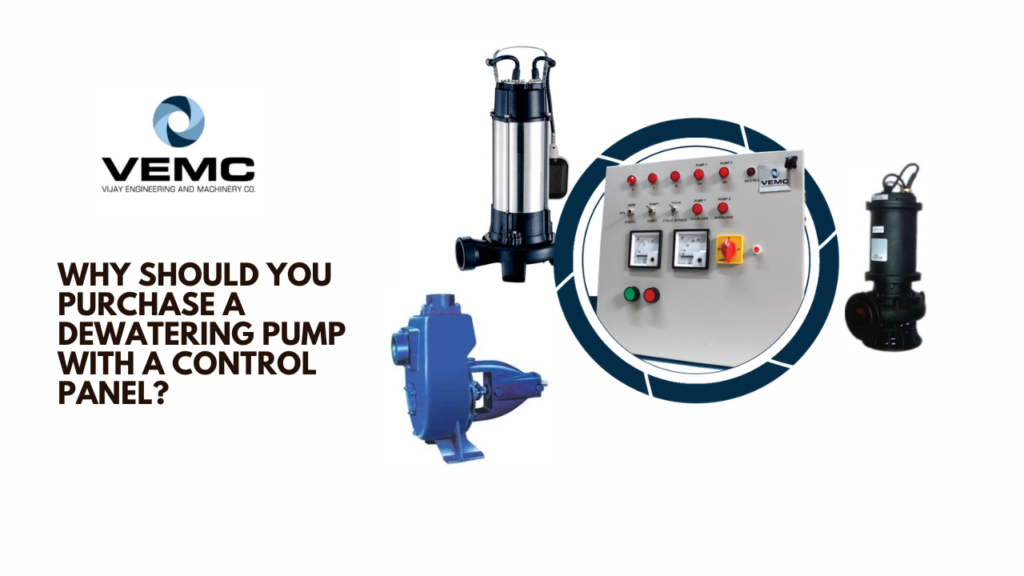

What are dewatering pumps?

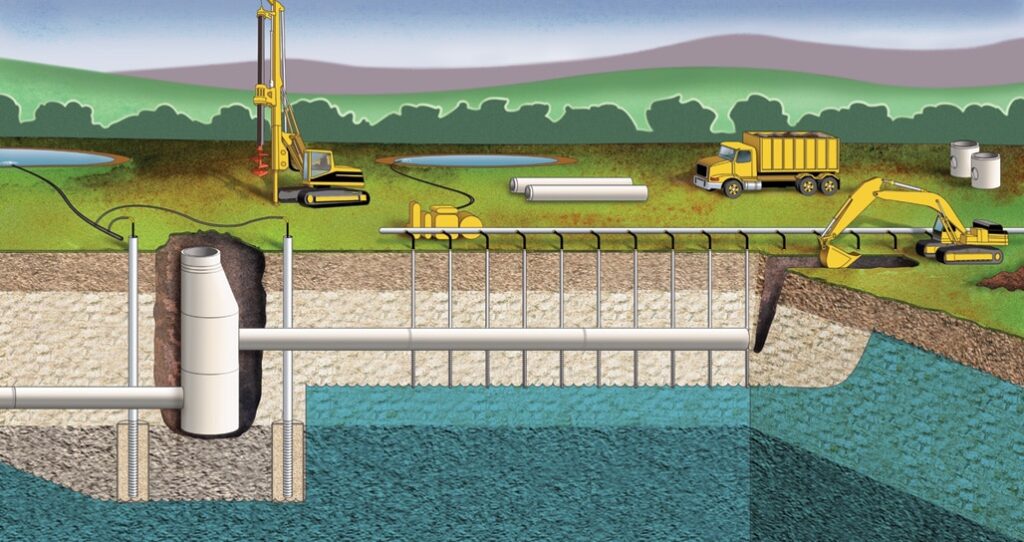

A dewatering centrifugal pump is typically used to remove water from one site and move it to another. A dewatering pump has a variety of applications in the construction, mining, mill, and municipal industries. A dewatering pump is useful for use in any area that needs to be maintained dry and clean, such as roadways and construction sites. A dewatering pump’s efficient flood control, inland wastewater management, and fast drainage features make it especially useful during the monsoon season. In reality, a dewatering centrifugal pump performs the same tasks as any other pump. The dewatering pump uses an impeller with a blade to initiate and maintain the flow of water, just like a centrifugal pump does. The fluid enters the impeller eye, a tiny area of the impeller. The water flow is then gathered from this location and directed to the diffuser, which is a discharge nozzle with a cone-shaped shape. This is the point where the water’s velocity is lowered and the energy of the flow of the water is converted to pressure energy.

For maximum effectiveness, the water is then evacuated from the pump following the aforementioned procedure at an angle of 7 to 10 degrees.This is the dewatering stage. Electric motors are typically employed to speed up this procedure. Some pumps, though, might employ various motor types. A sturdy and compact design, light weight for transportation, high fluid capacity, and high abrasion resistance are special properties of a dewatering pump that enable the most effective handling of muddy water and slurry.

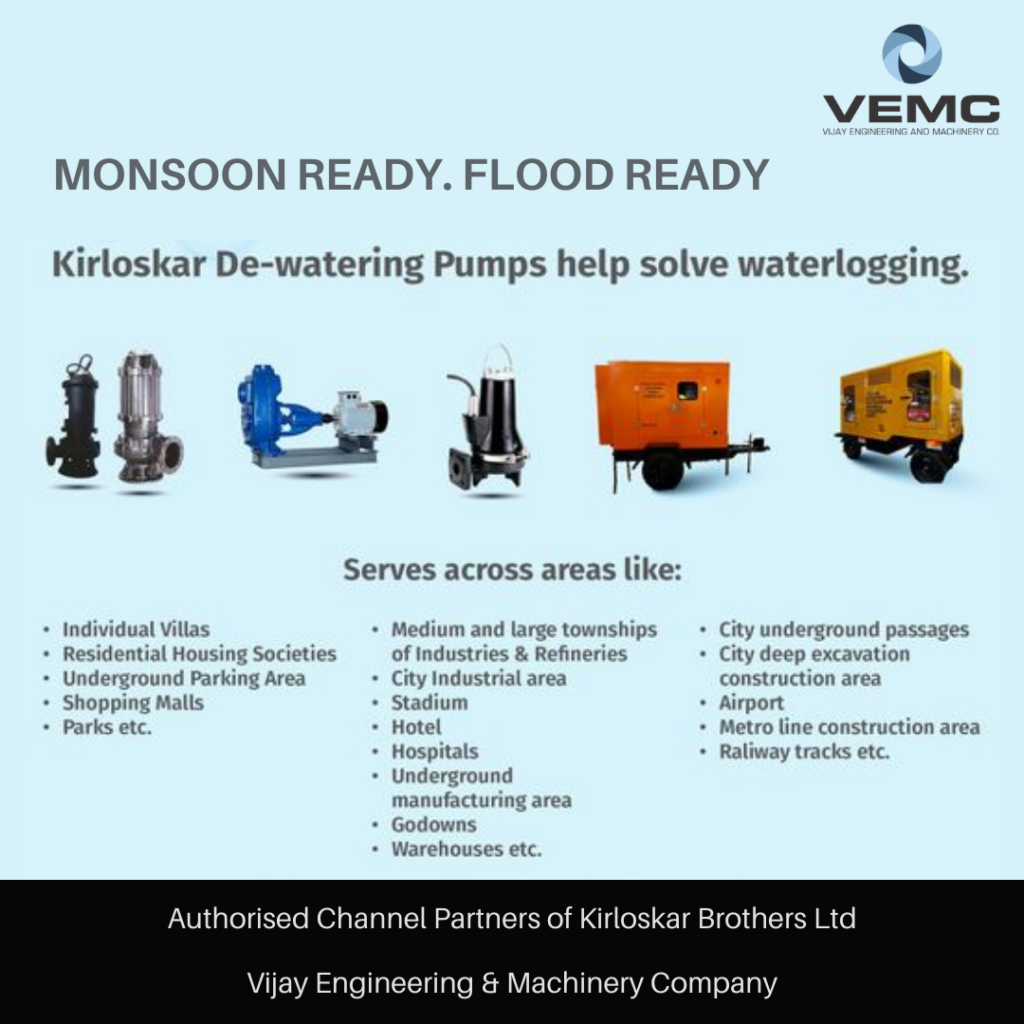

Why should you go for Kirloskar dewatering pumps?

Kirloskar Brothers Limited provides a selection of dewatering pumps to remove water inundation caused by significant rainfall. These pumps are a great option for draining water-logged areas in residential, commercial, and municipal settings since they are quick to install, simple to use, and function well.

KBL’s pumps are designed using cutting edge technology and are extremely and durable. For the highest quality of performance and reliability, opt for KBL’s range of dewatering pumps particularly in the monsoon season.

For more information on industrial pumps, motors, and other equipment, feel free to contact us at +91 98199 07445. We would be glad to assist you in finding the best match for you based on your requirements. VEMC is an authorized dealer of Kirloskar dewatering pumps and provides end-to-end project management services to its clients. We are ISO 9001:2015 certified and a pioneer in the field of electromechanical engineering products, allied equipment, and services. For inquiries, contact us at marketing@vemc.co.in.