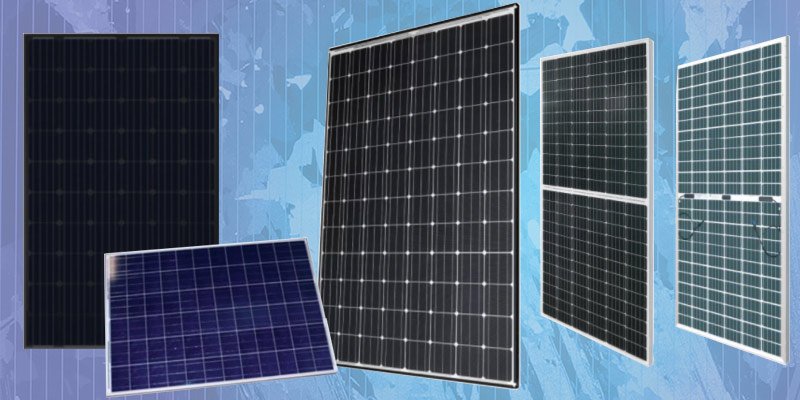

Solar panels are an effective and environment-friendly choice for your commercial spaces, to cut down on harmful pollution. It not only helps the planet, but also enables energy efficiency in a sustainable way. However, since the panels are located outdoors, they may attract various outside elements such as birds. Many people are unsure about whether solar panels hurt birds or vice versa.

In this blog, we discuss in detail about the relation between birds and solar panels.

Solar panels and birds

It’s common knowledge that birds may find a good nesting ground in your solar panels and may soil your gutters and panels. What should you do about it? And how should you save the birds as well as your solar panels? Let’s learn more.

Do solar panels benefit birds?

This may come as a surprise but solar panels benefit birds. Currently, some of the primary sources of electricity are oil, coal, and natural gas. They cause carbon pollution in the air and form a layer in the atmosphere that traps heat. Apart from various issues around global warming, it also leads to birds having to find alternate homes. Hence, solar panels are beneficial to birds as they provide them and their young ones with warmth and shelter.

Do solar panels attract birds?

Yes, just like windows, solar panels have reflective surfaces, and such surfaces usually attract birds.

Do solar panels kill birds?

Solar panels don’t kill birds directly. The reflective surfaces of solar panels often resemble water when birds are flying above. The appearance of moving water makes them dive, which eventually hurts them and sometimes, kills them.

Do birds harm solar panels?

Solar panels usually have space between the panels and the roof that allow wiring and ventilation. The shade in these spaces is ideal for birds to take shelter.

Birds usually build nests here as well as leave droppings, broken eggs, etc., under the space available. When these accumulate, they reduce the airflow needed to prevent solar panels from overheating. They can also flow into the gutter, leading to blockages and foul odour. It can also collect on top or under the panels and it’s best to get them cleaned as soon as possible.

Damages from small critters

Critters such as squirrels also enjoy nesting under solar panels and may cause harm by chewing on exposed wires. This could lead to solar panels running inefficiently.

Another serious concern is that nesting materials such as leaves, debris, and chewed wires may also lead to fire hazards.

How to protect your solar panels from birds?

There are several options to look at:

- Wire Mesh – Building a wire mesh along the edges of the solar panel can help stop birds from nesting under the system. This can also prevent the accumulation of debris.

- Roof Spikes – They don’t necessarily hurt birds but make it difficult for them to nest.

- Plastic Predators – Decoys are a great way to ward off birds since they can’t differentiate between artificial and real birds. Like scarecrows, an owl with a swivel head can be very effective in scaring birds away.

Importance of Solar O&M

These various factors can affect the output of your solar panels. Proper operation and maintenance can enhance the lifespan of these systems. The frequency and degree of maintenance of solar systems depend on the installation type, system configuration and location of the setup. You can choose from various types of services such as performance monitoring, preventive maintenance, and corrective maintenance.

VEMC, one of the top solar companies in Mumbai, provides solar panel installation in Mumbai. VEMC provides solar O&M services as well. For more information on our products and help selecting the right ones for you, contact us at +91 98199 07445. With over 72 years of industry experience, VEMC is ISO 9001:2015 certified and a pioneer in the field of electromechanical engineering products, allied equipment, and services.