Kinetic pumps propel large volumes of fluid at low pressure, while positive displacement pumps move relatively small volumes of fluid at high pressure. Before further pressure or velocity can be increased, a certain level of pressure is necessary to get the fluid to flow into the pump. Cavitation (the creation of a void space in the pump that is typically filled with liquid) will take place if the inlet pressure is too low. Cavitation is frequently caused by the vaporization of liquid in the suction line. A greater pressure zone causes the vapor bubbles that were brought into the pump with the liquid to collapse, which causes excessive noise, vibration, corrosion, and erosion. The necessary inlet pressure, the capacity against a specified total head (energy per pound owing to pressure, velocity, or elevation), and the % efficiency for pumping a certain fluid are crucial features of a pump.

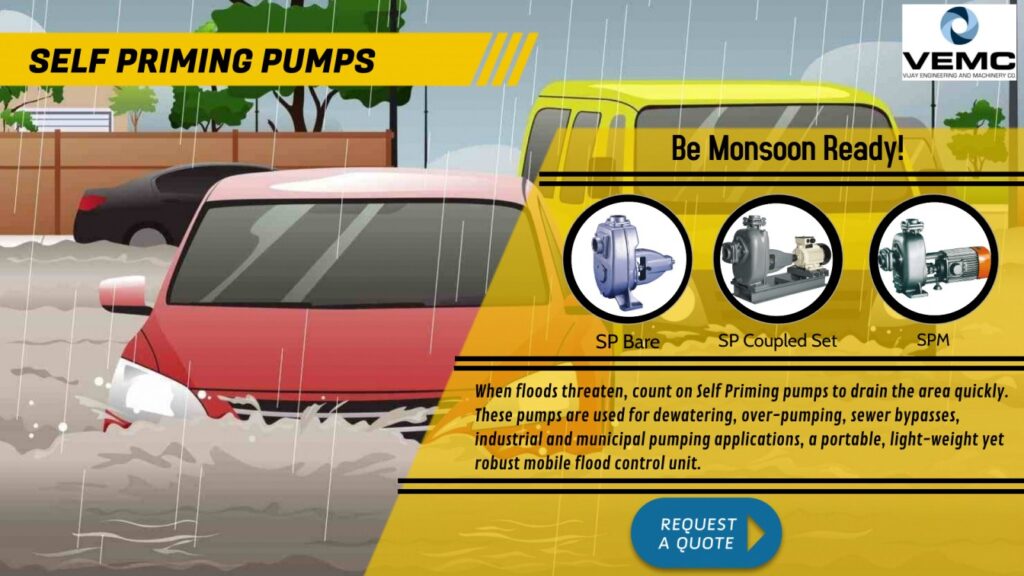

What is an SP Coupled Pumpset with IE5 motor used for?

- Handling mild chemicals, effluents, sewage, ashwater, etc.

- Handling flood and rainwater. foundation, trench, and pit drainage

- Water pumping from ships, ports, and docks. removing stored water from parking lots, roads, and basements, etc.

- Cooling water for shovels, piling equipment, and marine motors.

If your business has any of the above needs, you should consider contacting industrial water pump dealers in Mumbai to help you out.

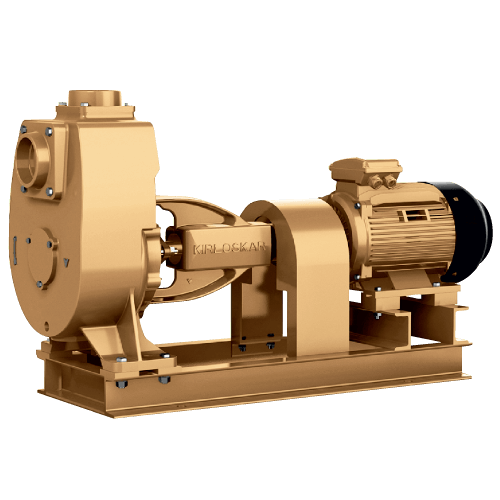

Why go for a SP coupled pumpset with IE5 motor?

- They function with extremely high efficiency, leading to more productivity with lesser energy consumption.

- Lower operational costs and lower life cycle costs.

- For the same amount of fluid to be pumped, up to 16.5 percent less energy is required.

- They contain superior F-Class insulation.

- Strong construction to handle significant power fluctuations ensures the equipment’s dependability, safety, and longevity.

- High efficiency AC induction motor design results in tough and best suited to work in a variety of field circumstances.

- Since permanent magnets, additional accessories, and control equipment are not used, local operations, maintenance, and servicing are simple.

- They come with a CED Coating applied as an effective method of preventing oxidation and erosion.

- Longer life due to corrosion resistance.

- They are self-priming pumps which are useful if a pump has to be located above the level of the liquid to be pumped.

- Its ability to handle suspended soft materials up to 10.5 mm in size without clogging makes it ideal for dewatering and wastewater applications as dewatering pumps.

- Ensure consistent performance and extended component life by reducing vibrations to prevent components from damage during operations.

For more information on industrial pumps, motors, and other equipment, feel free to contact us at +91 98199 07445. We would be glad to assist you in finding the best match for you based on your requirements. VEMC is an authorized dealer of Kirloskar dewatering pumps, and provides end-to-end project management services to its clients. We are ISO 9001:2015 certified and a pioneer in the field of electromechanical engineering products, allied equipment, and services.