A reciprocating compressor or piston compressor uses pistons that are aided by a crankshaft. The main function of the reciprocating compressor is to increase the level of pressure in gases.

A reciprocating compressor has several components that aid in the passage and compression of the gas. Each of these components plays a specific role and is equally necessary for the smooth functioning of the reciprocator compressor.

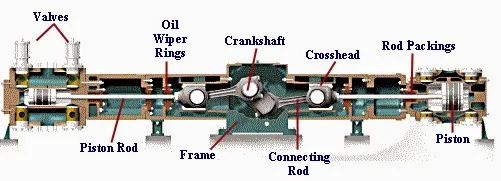

Let’s take a closer look at the basic components of a reciprocating compressor:

Frame

The frame or crankcase is a sturdy structure that encloses all the rotating components. ELGI air compressor frames are square or rectangular shaped. In Integral Compressors, the frame is fitted to both the compressor and engine-powered cylinders which are driven by one crankshaft.

Cylinders

Cylinders play a crucial role in containing the air that needs to be pressured. A compressor could have either large low-pressure cast iron cylinders or small high-pressure steel compressors. Cylinders help to keep the reciprocating compressor cool during the compression cycle. Reciprocating compressor dealers might also show you cylinders with replaceable liners that can be changed when damaged or worn out.

Distance piece

The distance piece is an intermediary component that attaches the low-pressure cylinders to the frame of the compressor. Due to the distance piece in ELGI air compressors, the cylinders can be detached if required. A distance piece could have a single, double or extra-long compartment arrangement.

Piston

The piston is what compresses the gas within the cylinder. It is typically made up of a strong and heavy material that does not react with the gas in the chamber. You might find pistons made from aluminium or cast iron when looking for compressors at reciprocating compressor dealers.

Piston rings

Piston rings are placed around the piston. These rings could be either metallic-like bronze or non-metallic like a fluorocarbon compound. They are subject to friction as they come in contact with the inner walls of the cylinder and might wear out easily. Piston rings might have to be replaced regularly but help to protect the piston from damage due to friction.

Cross head

The piston is inserted into the cylinder bore with the help of a cross head. Narrow pistons used with a cross head are more efficient as they can accomplish longer strokes.

Crankshaft

This is what drives the piston. It is attached to the electric motor shaft on one end and to the piston on the other. Higher powered crankshafts are made of forged steel while those operating less than or equal to 150kW are made of ductile iron.

Connecting rod

The connecting rod connects the crankshaft to the piston and enables its upward and downward motion. The connecting rod is typically made of the same material as its corresponding crankshaft.

Valve

The valves of a reciprocating air compressor ensure that the gas flows in only one direction. On one side of the cylinder, there are inlet valves while on the other there are outlet valves. Valves are of three types:

- Ring valve

- Poppet valve

- Plate valve

Bearings

Bearings complete the structure of the reciprocating compressor. They ensure the proper radial and axial positioning of components of the compressor including the crankshaft, connecting rod, and cross head.

If you are looking for reliable ELGI air compressor dealers make sure that you are first clear about the type of compressor you need for the job at hand. For more information on reciprocating air compressors and other equipment, feel free to contact us at +91 98199 07445. We would be glad to assist you in finding the best match for you based on your requirements. VEMC is an authorized dealer of Kirloskar dewatering pumps and provides end-to-end project management services to its clients. We are ISO 9001:2015 certified and a pioneer in the field of electromechanical engineering products, allied equipment, and services.