Although the benefits of switching to a more sustainable renewable energy like solar are quite well known in India by now, what is less talked about are the virtues of storing solar energy for use in the future. Despite the cost of energy storage sometimes continuing to be a barrier, such as in the case of using Li-Ion batteries for the purpose, there can also be commercial benefits to the practice.

You can meet all your energy needs completely with solar storage

In a state where tariff rates are high, it would make sense for a factory using solar energy to maintain the solar capacity below the contract demand. If 20 to 50 percent of the total energy requirement can be met by consuming energy generated by the rooftop solar installation, the entire 100 percent can be met by combining both this as well as the energy storage to keep it cost-efficient even at peak hours of usage like the afternoons and evenings.

You can increase financial savings significantly

Storing solar energy for later use can reap 20 to 30 percent in financial savings for clients. What’s more, this can be provided in the OPEX financial model too. For those clients that are unable to install more than 1MWp of solar panels through net metering, adding a solar energy storage component with battery storage can make up for it.

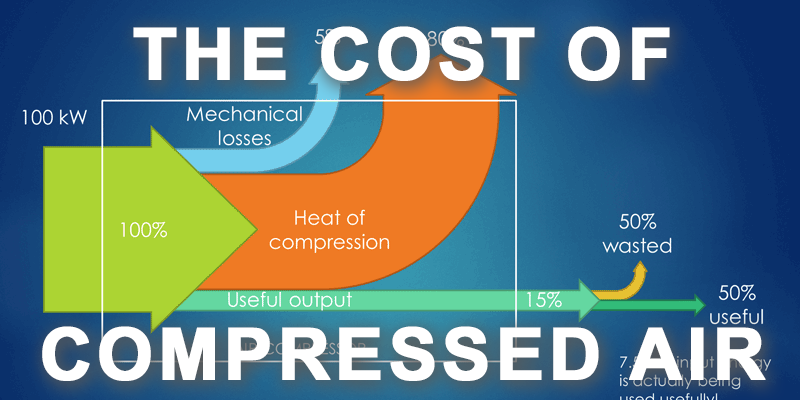

Ramp up/down demands for thermal power can become more gradual

Solar capacity firming is a concept where a solar installation is operated along with a thermal power plant. The fluctuations in solar energy output call for abrupt changes in balancing the demand for thermal power. Not only does this put pressure on the thermal power plant and result in inefficiency, it can also incur penalties or a higher tariff. By storing energy, this can be smoothened out and prevented.

A solution for industries using batch production

For industrial applications which require batch processes to be run with an online UPS, solar energy storage provides an alternative solution. Additionally, it can even be stacked up for several different applications even without using solar.

Cleaner and cheaper alternative to diesel generators

Storing solar energy is a far more efficient and sustainable solution than using conventional diesel generators which can cause pollution and drive up carbon footprint.

With rapidly improving technology and gradually reducing costs, solar energy storage can become the predominant solution across industries in the near future.

VEMC is a well-established solar services company that provides comprehensive project management services to its clients. We are ISO 9001:2015 certified and a pioneer in the field of electromechanical engineering products, allied equipment, and services. For inquiries, contact us at +919819907445.