Variable Frequency Drive or VFD are control panels that help control the speed of electric motors and feed pumps used in various industrial facilities. Each motor has a different frequency and voltage and hence, a separate VFD control panel is required to monitor and control them.

With VFD panels, you can bring multiple motors with variable frequencies and voltages under one roof. This will also protect your motors from moisture, corrosion, dust, and other damaging elements.

VFDs are a crucial part of any manufacturing plant. Without them, the plants will not be able to maintain their output consistently. It can also cause failures that can severely hamper the production capacity of the plant.

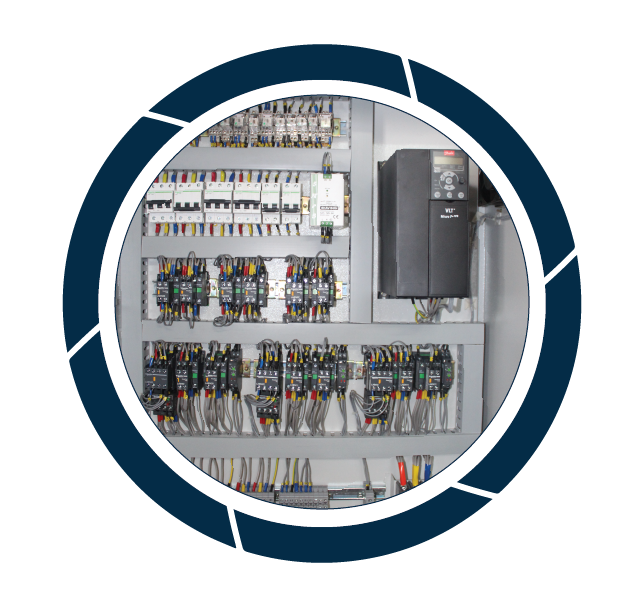

Like other control panels, VFDs comprise a range of equipment such as:

- Harmonic filters

- Protective equipment such as relays, circuit breakers, and stabilizers

- A bypass control to keep the VFD operational in all conditions

- Programmable Logic Controllers (PLC) for advanced control

- Communication equipment such as switches and modems

- Temperature control equipment such as air conditioner or anti-condensation heater

- Motor starters

Benefits of a Variable Frequency Drive (VFD)

Does your industrial facility need VFD? Absolutely! Here are the top 4 reasons why you should get a VFD for your manufacturing unit:

- Power switching and protection – VFD control panels act as an intermediary between the power source and your equipment. In case there is a short circuit or a power overload, it will cause the circuit breaker of the VFD to trip. This way, your drive or any equipment connected to the line will not get affected.

- Speed backup – The VFD panel doors usually have a frequency control potentiometer. This helps send command signals to the motor as per the operator’s settings. In case the VFD fails, a bypass switch helps keep the motors functioning.

- Equipment protection – Any manufacturing plant workplace is filled with moisture, dust, and other damaging particles. It can be cumbersome to protect your equipment from these. Long-term exposure to these materials can damage the tools permanently. One of the major risks is chemical accumulation on the open connections that can negatively impact performance. Moreover, dirt accumulation can reduce the lifespan of the equipment too.

- Visual control – VFD panels can provide crucial real-time data on the drive’s energy consumption, frequency, and other diagnostic data that operators require. Operators can also use the embedded controls to shift frequencies or take precautionary measures as per the monitored values.

NEMA Ratings

VFD control panels have different ratings from the National Electrical Manufacturers Association (NEMA). There are 13 ratings, some of which are:

- Type 1: General purpose, for indoor use, protection against solid foreign objects

- Type 2: Similar to Type 1 but with extra drip shields

- Type 3: Protecting the equipment from external weather conditions such as rain

- Type 3R: For outdoor use

- Type 4: Water-tight, shielding equipment from at least 65 GMP of water

You can choose a specific protection by VFD panels based on the NEMA guidelines for the best usability and equipment protection.

How can VFDs reduce energy consumption?

VFDs can reduce energy consumption significantly and help save production costs. Traditionally, motors would need valves and dampers to control pumps and fans. This would consume huge amounts of energy. VFDs can do the same without consuming so much energy. Moreover, the flexibility to adjust fan and pump speeds offers more control to operators to save energy.

Why VEMC VFD panels? VEMC has all the resources you need to get the right VFD control panel for your system. Our excellent team of experts will offer end-to-end services right from the design selection to delivery, installation, and maintenance support. We are a 72-year young organization with ISO 9001:2015 certification and are CRISIL MSE-1 rated. We are pioneers in the field of electromechanical engineering products, allied equipment, and services. We will be happy to help you choose the right VEMC control panels for your manufacturing plant. Reach out to us at +919819907445.