Table Of Content

- Understanding the sources of noise in air compressors

- Strategies for reducing air compressor noise

- Regulations and standards for noise levels

While air compressors are a great source of power across industries and business facilities, these could often disturb the tranquility of a residential house. In these settings, it is necessary that the right strategies for noise-free operation are put in place. VEMC is the leading ELGi compressor dealer in Mumbai and in this blog, we tell you all about reducing the noise produced by your air compressor.

Understanding the sources of noise in air compressors

Before we take action against the noise, it is necessary to understand where it is coming from. The most common sources of noise in an air compressor are:

- Intake: The intake of air by a compressor can produce noise due to shifts in pressure or turbulent torrents entering your air compressor.

- Discharge: Just as air entering your compressor forcefully produces noise, the compressed air pushed out through the discharge valve can also produce a significant amount of noise.

- Motor: Over a period of time, due to friction, wear and tear, or lack of lubrication, the motor of your air compressor can also start making noise.

- Vibration: An air compressor is a system of moving parts which can rub against each other during operations, creating a lot of vibration and noise. It may also be caused by simpler reasons like unsteady floor where the compressor rests.

Strategies for reducing air compressor noise

- Enclosures: If your compressor is producing noise beyond your tolerance levels, you can simply cut it off from the rest of your home or factory floor by building a physical enclosure around it. Soundproofing the walls of the enclosure can also go a long way in absorbing the noise.

- Silencers: Air compressor silencers or mufflers are effective devices available in the market which greatly help reduce the noise produced by an air compressor.

- Sound-absorbing material: Unlike steel or concrete, sound-absorbing material absorb rather than reflect the noise produced by a compressor. These include acoustic panels, foam or wood.

- Proper installation location: Installing the compressor in a separate dedicated room can help prevent the noise from affecting the rest of the house or factory. Place the compressor away from walls and corners to prevent the noise from rebounding and amplifying.

Regulations and standards for noise levels

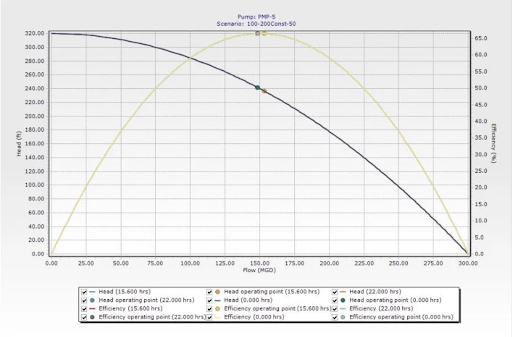

Noise pollution is a massive concern when you’re investing in an air compressor for your home or factory. When buying a compressor in India, you must be aware of the regulations and standards set as per the Noise Pollution (Regulation & Control) Rules, 2000. Here are the noise levels acceptable in various settings as per the rules:

| Area code | Category of Area / Zone | Limits in dB(A) Leq | |

| Day Time | Night Time | ||

| (A) | Industrial area | 75 | 70 |

| (B) | Commercial area | 65 | 55 |

| (C) | Residential area | 55 | 45 |

| (D) | Silence Zone | 50 | 40 |