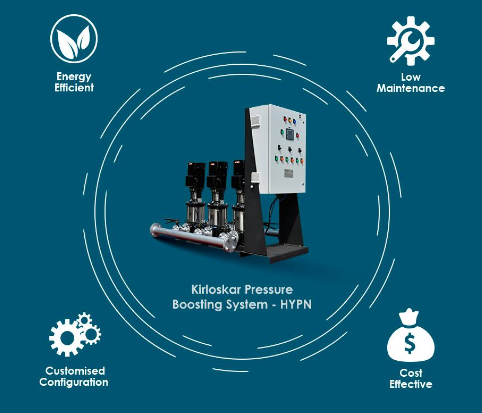

Kirloskar has come up with a state-of-the-art solution, known as the Hydro-Pneumatic (HYPN) system, for maintaining constant water pressure and serving changing water demand in buildings automatically. It predominantly finds use in commercial facilities such as hotels, hospitals, and industries. HYPN simply converts conventional pumping systems into a smart, responsive, and highly efficient automatic pumping systems.

As soon as the pressure falls below predetermined levels, the HYPN system turns on the motors to maintain a constant pressure level. On the other hand, it also eliminates the unnecessary functioning of the pumps. The HYPN system is low maintenance and durable, making it a highly cost-effective system. Due to its ability to match the pressure exactly with the demand, the HYPN system can also control the energy consumption, further reducing the cost.

Apart from the cost benefits, Kirloskar has added a significant feature to the HYPN system. It integrated with remotely accessible smart devices, like mobiles and iPads, which enables customers to monitor various parameters of the HYPN system without physical presence. Its predictive analysis prepares customers about the likelihood of errors and breakdowns in advance. This further reduces the hidden costs associated with sudden breakdowns and unforeseen repairs. Besides, the remote monitoring system also eliminates the need for physical checks by field inspectors, thus, lowering human resource costs.

HYPN system is only as effective as its pumps. Kirloskar offers a wide range of pumps to work with the HYPN system and meet the clients’ unique needs. Inline, end suction, sump pumps, split case pumps, and VT pumps, among others, work seamlessly with the HYPN system. This enables the HYPN system to adapt to several industry verticals, like pharmaceuticals, mining, textiles, steel, railways, hotels, metros, etc., for their distinct requirements.

Kirloskar has been awarded India’s prestigious accreditation for HYPN, namely the India Design Mark (IDM), which symbolizes product excellence in quality and innovation. It is the country’s first HYPN manufacturer to receive this accreditation, which speaks volumes about the tremendous planning, research and development, innovation, and quality assurance while manufacturing this unique pumping system.

Lately, Covid-19 hospitals in Delhi, Uttar Pradesh, and Kerala found extensive use for KBL’s HYPN system in maintaining the water supply at their facilities.

For further information on industrial pumps, motors, and other equipment, contact us on +91-9819907445. As a leading industrial water pump supplier in Mumbai, we would be happy to assist you in finding the best match based on your requirements. VEMC is an authorized Kirloskar dealer. It is ISO 9001:2015 certified and a pioneer of electromechanical engineering products, allied equipment, and services.