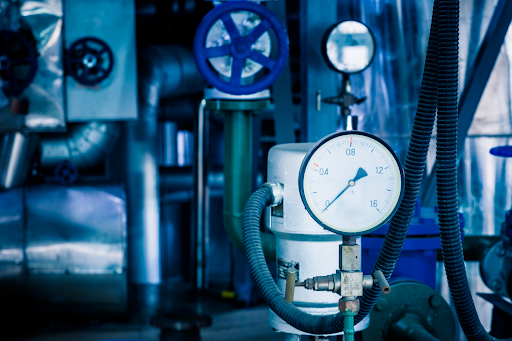

Residing in high-rise apartments has several perks. Starting from stunning views to modern amenities, you get peace of mind with secured living. But wait, there are some drawbacks that you cannot ignore. From a weak shower flow to a trickling tap, facing inconsistent pressure is extremely frustrating.

If you too face the same struggle of inconsistent supply, that’s a clear sign that you need a pressure boosting pump. These pumps ensure uniform water pressure across all floors, showers, taps, and appliances. Thus, now you don’t need to wait anymore for the tank to fill up.

Get Rid of Low Water Pressure

In multi-story buildings, long pipe networks and gravity tend to reduce the water pressure. Especially on the upper floors. If your washing machine or shower systems struggle because of inconsistent supply, which is a clear sign you need a pressure boosting pump. It not only improves convenience but also protects your home’s plumbing from unnecessary strain.

Steady water flows every time

Appliances such as washing machines, geysers, and showers perform best when they receive consistent water pressure. Whether you are doing the laundry while someone’s showering or washing dishes during peak hours, the system ensures that it receives uninterrupted water flow.

Therefore, it improves convenience along with protecting your home’s plumbing from unnecessary strain.

Energy-Efficient and Whisper-Quiet Design

Today’s pressure boosting pumps are engineered to deliver high performance while consuming less power. Advanced motor designs ensure minimal noise, which makes them perfect for residential spaces. So, while your pump works hard behind the scenes, your home remains efficient and peaceful.

Smart and Automatic Operation

Manual control is no more in the scene. Nowadays, pressure boosting pumps come with automatic on and off features along with smart pressure sensors. It starts when water flow drops and stops when ideal pressure is achieved—all automatically. Ultimately, you save both effort and energy. Thus, this kind of automation is useful in apartments where multiple outlets are used simultaneously.

Easy Maintenance and Long-Term Reliability

When you choose a well-designed pressure boosting pump, you get the sense of relief that it requires minimal upkeep. Models that are from trusted industrial pump suppliers are built to withstand years of use with simple periodic maintenance. VEMC ensures that you get quick access to spare parts along with expert servicing. Hence, it ensures that your investment delivers consistent value over time.

Why Choose VEMC for Expert Solutions

Consistent water pressure is a necessity for comfortable urban living. A pressure boosting pump guarantees a steady flow of water, protects appliances, and enhances daily convenience.

VEMC, being one of the most trusted industrial water pump suppliers in Mumbai, offers a wide range of advanced pumps that are suited for residential and industrial needs.

For expert advice and installation support, reach out to us at: +91 8976951701 | +91 98199 07445 | 022 43436655 | 022 43117133 Email: marketing@vemc.co.in

Explore our full range of pressure boosting systems here.