In industries like chemicals and pharmaceuticals, pumps are constantly exposed to aggressive fluids. The wrong choice of Material of Construction (MOC) can lead to early failures, safety risks, and mounting costs. For plant engineers looking up “pump manufacturers near me”, understanding pump MOC is one of the most important steps in building a reliable and efficient system.

What Does MOC Mean in Pumps?

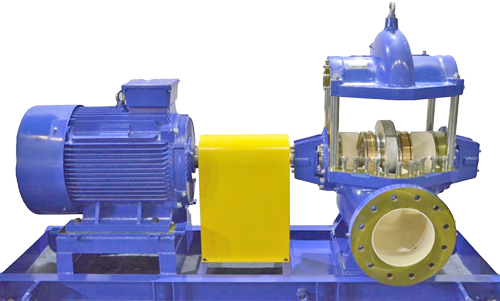

The Material of Construction refers to the metals, alloys, or linings used to build key pump components such as casings, impellers, and shafts. Since every process fluid behaves differently, choosing the right MOC ensures long service life and safe operation.

Common MOCs Used in Process Pumps

Leading brands like Kirloskar offer pumps in a variety of materials to handle diverse fluids. Some widely used MOCs include:

- Cast Iron (CI): Cost-effective, ideal for non-corrosive water applications

- Stainless Steel 316 (SS316): Excellent for mildly corrosive fluids, widely used in pharma

- Duplex Steel: Superior resistance to pitting and stress corrosion

- Hastelloy: Best for highly oxidising and reducing agents

- Alloy-20: Designed for sulphuric acid and similar aggressive chemicals

- PTFE-lined Components: Perfect for highly corrosive acids and solvents

As trusted Kirloskar pump dealers, VEMC ensures the right match between fluid properties and MOC.

Why the Wrong MOC is a Risk

Choosing incorrectly can cause:

- Corrosion: Rapid thinning of pump walls, leading to leaks

- Erosion: High-velocity abrasive fluids wearing out parts

- Stress Cracking: Structural damage under combined chemical and mechanical stress

- Pitting: Localised attack, often hidden until major failure occurs

A single oversight in MOC selection can compromise product purity in pharma plants or lead to downtime in chemical production.

How to Select the Right MOC

Engineers rely on chemical compatibility charts to evaluate MOCs against specific fluids. Factors like temperature, pressure, and concentration must also be considered. For example:

- Sulphuric acid often requires Alloy-20

- High-temperature caustic soda works better with Duplex Steel

- Solvents in pharma may demand PTFE linings

Selecting the correct MOC at the design stage avoids costly retrofits later.

Long-Term Cost Benefits

While exotic materials may cost more upfront, they lower lifecycle costs by reducing downtime, repairs, and product losses. Proper MOC selection is not just a technical decision; it’s an investment in reliability and safety.

The Takeaway

Getting pump MOC right ensures process integrity, safety, and efficiency. At VEMC, we’ve worked with leading chemical and pharmaceutical companies as trusted pump manufacturers and authorised Kirloskar pump dealers. Our team helps you select the ideal MOC for your application and avoid premature failures.

Explore our full range of Kirloskar pumps or learn more about VEMC’s expertise here.

For expert support, reach out to us at +91 8976951701 | +91 98199 07445 | 022 43436655 | 022 43117133 or email marketing@vemc.co.in.