Air compressors form an integral part of many industrial operations but they are also known to consume significant amounts of energy. In fact, a large portion of the energy input is lost as waste heat. However, this excess heat can also be recovered and utilised for other purposes. Let’s find out how ELGi EG Series compressors, with their advanced heat recovery capabilities, are helping businesses harness this wasted energy.

Energy Input vs. Wasted Heat in Air Compressors

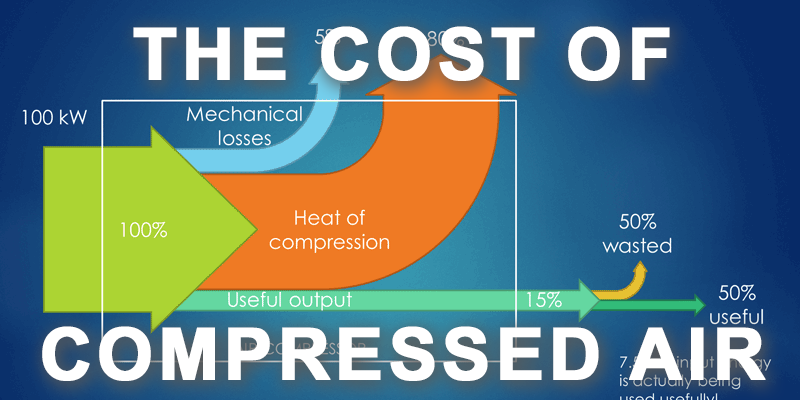

Air compressors typically consume large amounts of electricity to convert electrical energy into mechanical energy. However, a significant portion of this energy is lost as heat. In a conventional air compressor, this waste heat accumulates in the motor, compressor components, and cooling system. Fortunately, up to 76% of this heat is recoverable and can be redirected for useful applications.

Principles of Heat Recovery in Compressors

The heat recovery process in ELGi EG Series compressors involves capturing and using the waste heat generated during the compression cycle. There are several key components involved in this process such as cooling oil, intercooler, and aftercooler.

Applications of Heat Recovery

Heat recovered from ELGi EG Series compressors can be used in several applications like:

- Space Heating: The recovered heat can be used to warm industrial or office spaces, reducing the need for additional heating sources.

- Boiler Feedwater Preheating: The heat can be used to preheat water for boilers, lowering the amount of energy needed to bring the water up to the required temperature.

- Process Water Heating: Many industrial processes require heated water. Using recovered heat for this purpose reduces energy consumption and lowers operational costs.

Cost Savings Potential

The potential cost savings from heat recovery can be substantial. For instance, a business using ELGi EG Series compressors offered by reputed ELGi air compressor dealers may recover up to 50% of the total energy consumption through heat recovery. By recovering even 50% of heat, the company could save up to 38 kW in energy costs. If annual operating hours are 8,000 and the cost of electricity is ₹8 per kWh, whereas the total heat recovery is 38 kW, then the annual savings will be: 38 kW × 8,000 hours × ₹8/kWh = ₹2,432,000 annually. This simple calculation shows how heat recovery can pay off in a relatively short period.

Environmental Benefits

In addition to cost savings, heat recovery from ELGi air compressors contributes to CO₂ reduction. By using recovered heat, businesses can reduce their overall energy consumption, thereby lowering carbon emissions. This aligns with broader sustainability goals and helps companies reduce their environmental footprint.

Integration Considerations and ROI Analysis

When considering heat recovery, businesses must evaluate factors like the initial investment, installation complexity, and compatibility with existing systems. The ROI for heat recovery systems can be realised within 1-3 years, depending on energy usage, system efficiency, and the cost of energy.

As a trusted air compressor dealer in Mumbai, VEMC offers ELGi EG Series compressors that are designed for durability, performance, and energy savings. Contact us today at +91 8976951701, +91 9819907445, 022 43117133 or email us at marketing@vemc.co.in to explore our wide range of products and services.