In areas with high water table, constructing a building can be quite challenging due to nuisance seepage. In fact flooding of basements could also cause some very serious issues like instability and even the collapse of the excavation. VEMC is the leading Kirloskar water pump dealer based in Mumbai, and in this blog, we take you through the effective solutions for dewatering high-rise building basements.

Challenges of dewatering deep basements

- There could be sudden flooding due to inflow of water from layers of rocks or soil.

- Seepage erosion or instability of the excavation site could pose serious risks.

- Base heave or piping failure could result due to groundwater uplift pressures.

- The retaining structures of the excavation such as concrete walls could come under pressure due to excessive hydrostatic loads.

Factors to consider when choosing dewatering pumps for high-rises

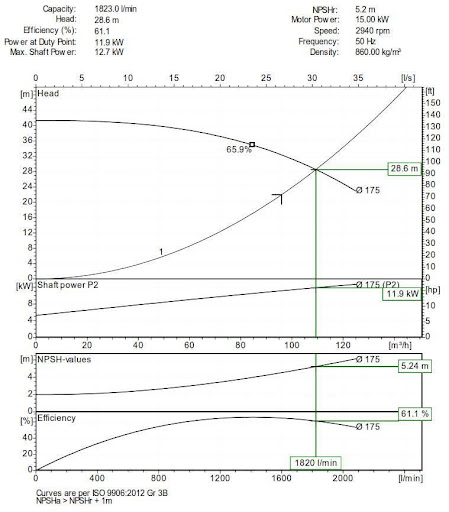

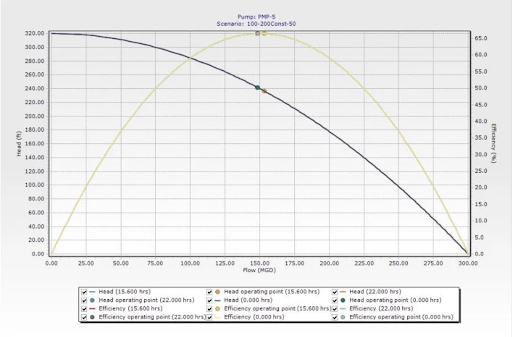

- Gravity and friction: To determine the pump size, consider where the water is to be pumped from and where it is going. Your pump must overcome both gravity as well as the frictional force along the length of the pipes.

- Longevity: Consider whether the pump will be able to perform consistently in conditions of floods. While ordinary pumps may crumble under pressure, dewatering pumps are typically highly water resistant and tend to have low wear and tear.

- Portability: For dewatering the excavation site fully, the pumps need to be moved around and hence must be portable. This can often result in rough physical handling which can only be survived by pumps with robust construction and design.

- Maintenance: Dewatering basements takes an enormous amount of time and effort, and also requires the engagement of dewatering pumps for prolonged periods of time. This naturally makes it difficult to maintain these pumps. When choosing a dewatering pump, prefer the ones with low maintenance requirements.

Different dewatering system configurations

- Wellpoints: In this configuration, wells are dug all round the excavation site and submersible pumps are installed in the shaft of each well. These pumps are then connected to a header pipe and groundwater is drawn up and discharged.

- Deepwells: Quite simply, a single or multiple wells are dug and submersible pumps are installed in each shaft to draw up water. These are best suited for deep excavations which require the removal of huge volumes of water.

- Flood control: This is a set of techniques which are used to prevent flooding of a basement or excavation site. It could mean digging tunnels or mine work. Site managers must have a range of pumps which can displace high volumes of water.

Dicharge management and environmental regulations

When dewatering a site, it is necessary to have an effective and well chalked out Dewatering Management Plan (DMP) for successfully dewatering the site while obeying the environmental regulations. Discharge monitoring for instance is the systematic measurement of quality and quantity of water being drawn and released into the environment. It could contain harmful pollutants like chemicals, heavy metals and suspended solids.

To know more about the effective dewatering solutions, get in touch with us by calling on 022 43436655 or emailing us at marketing@vemc.co.in. We at VEMC are the top-notch Kirloskar water pump dealer based in Mumbai.