Introduction

In many regions of India — including Maharashtra — borewells draw groundwater containing elevated levels of sand and other abrasive particles. When this gritty water passes through a submersible pump, it causes accelerated wear, reduced flow, frequent breakdowns and increased maintenance costs. This article explains why sand is a threat, and provides practical methods to protect your borewell submersible pump, maximise its lifespan and ensure uninterrupted water supply.

1. Why Sand & Abrasive Particles Damage Submersible Pumps

- When sand enters the pump impeller or bearings, it abrades metal surfaces, causing erosion, vibration, imbalanced rotation and eventual failure.

- Pumps installed in poorly screened boreholes often “pump sand” — a sign of mechanical stress and reduced lifetime.

- In borewells with sandy formation or inadequate gravel packing, fine particles migrate into the casing and get drawn in under suction pressure.

- Example: A case study from a farmer in Patna saw motor jamming due to sand ingress — the root cause being sand entering the pump motor assembly.

2. First Step: Assess Your Borewell Conditions

Before installing or servicing your pump, evaluate:

- Sand content: Conduct a “bucket test” of pumped water, observe sand deposition after 30 minutes.

- Screening/casing: Is there a well screen or gravel pack to reduce sand movement?

- Water yield & dynamic level: Low yield can cause pump suction to pick up sand from the formation.

- Pump placement depth: Pumps set too low in sandy formation risk sucking bottom sand.

- Existing wear signs: Unusual noise, vibration, reduced flow, increasing current draw all point to abrasion.

3. Pre-Installation Measures to Mitigate Sand Entry

- Install a gravel pack around the well casing: A layer of coarse gravel (~2-5 mm) around the screen helps trap fine sand and prevent it entering the pump suction.

- Use a well screen with appropriate slot size: A stainless steel or PVC screen sized to prevent fine sand (e.g., <200 micron) migrating into the pump.

- Casing integrity: Ensure the borewell casing is stable and free from collapsed sections which allow sand in.

- Proper pump depth: Position the pump at the correct depth (above the sand or low yield zone) to avoid sand ingress.

- Flush/develop the bore well post drilling to remove loose sand and debris prior to pump installation.

4. Choosing a Sand-Tolerant Submersible Pump

- Select a pump with sand-handling capability: e.g., hardened impellers, abrasion-resistant materials (stainless steel, high-grade cast alloy) designed for sand-laden water.

- Ensure the pump manufacturer gives specifications for maximum sand content (ppm or gram/litre) the pump can handle.

- Use proper control devices: Motor protection, dry-run cut off, voltage stabiliser — when sand causes flow drop, these protect the motor.

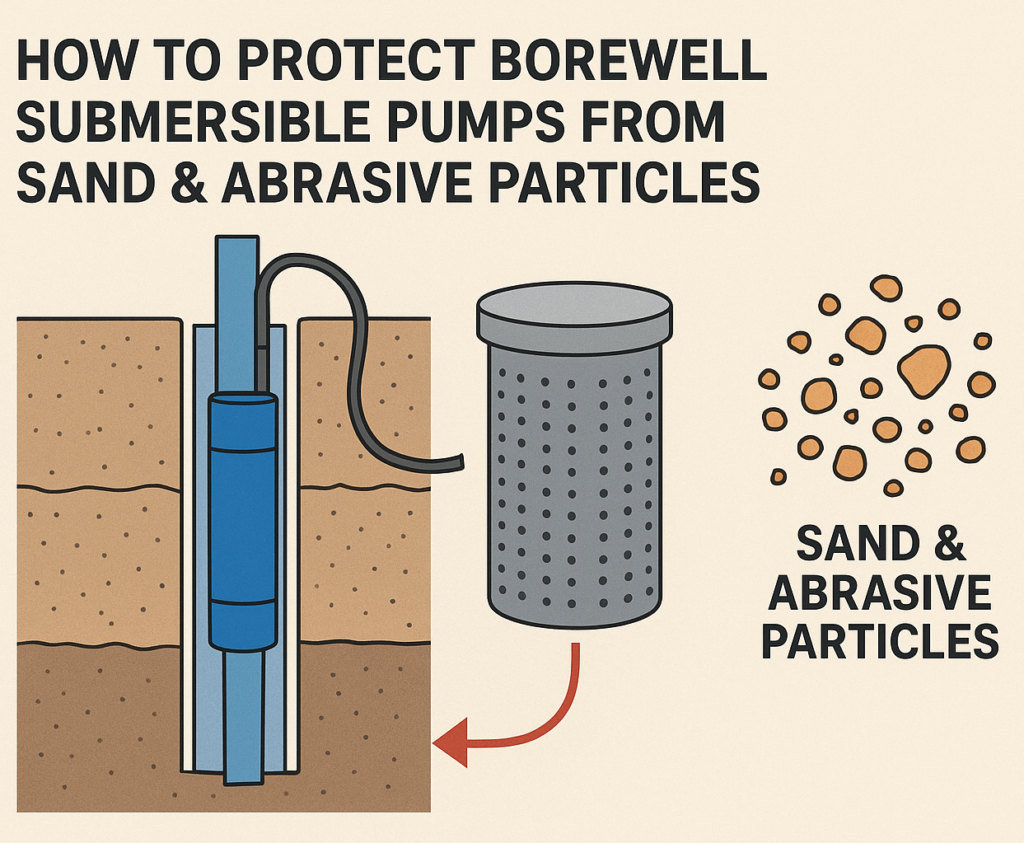

5. Filtration & Separation Solutions to Remove Sand

- Sand or grit separator (centrifugal type): Uses the pump’s flow to spin out heavier sand particles and discharge them separately, before water enters the pump.

- Spin-down filters or mesh screen filters: Installed above ground or near the pumphead, trap sand and flush it off manually or automatically.

- Routine flushing of separator: Regular check and emptying of sediment chamber ensures reliable operation.

- Sediment filter after the separator: For extra protection, a fine mesh or cartridge filter can capture residual fines.

6. Maintenance Best Practices for Longevity

- Schedule regular inspection of the intake screen, pump housing, cabling and motor current draw. Unusual vibration or current spike may mean sand damage.

- Monitor sand deposition in the pump discharge: If sand starts appearing in water or settling in tanks, action is required.

- Conduct wear inspections: Remove the pump yearly if feasible, inspect impeller, bearings, shaft for erosion.

- Maintain water level sensors/dry-run cut-offs: When water level drops, suction increases, sand ingress risk increases.

- Use voltage stabiliser/surge protection: Sand wear can cause increased load and motor overheating.

7. Troubleshooting Common Sand-Related Failures

| Problem | Likely Cause | Solution |

| Abrupt drop in flow rate | Sand clogging impeller or screen | Pull pump, inspect & clean screen/packing |

| Increasing motor current draw | Sand abrasion leading to bearing load | Replace impeller, use upgraded pump |

| Visual sand in discharge water | Sand entering suction | Improve gravel pack, fit separator |

| Frequent motor trips / overheating | Motor straining due to sand load | Install cut-off, check water levels |

8. Why VEMC is Your Trusted Partner

At VEMC (Authorised Channel Partner for Kirloskar Brothers Limited), we specialise in:

- Assessing borewell sand conditions in Maharashtra & India

- Recommending sand-handling submersible pumps and separators

- Providing after-sales maintenance, inspections and retro-fits

- Delivering cost-effective solutions that reduce downtime and extend pump life

Conclusion

Sand and abrasive particles are silent threats to borewell submersible pumps, especially in regions with sandy strata or high particulate content. By taking a proactive approach — evaluating borewell conditions, selecting the right pump, installing proper separation/filtration, and maintaining regularly — you can significantly extend your pump’s lifespan and reduce maintenance costs. Contact VEMC today to safeguard your borewell pump investment.

To learn more, speak with our expert team at VEMC for a site audit, pump assessment and tailored solution, email at marketing@vemc.co.in or call +91 9987099448