In urban and industrial areas vulnerable to flooding, selecting the right dewatering pump is crucial. With unpredictable power supply, challenging terrain, and time-sensitive operations, the choice between electric and diesel-powered pumps can significantly impact performance. Each option offers unique advantages — the real challenge is identifying which one aligns best with your application needs and emergency preparedness strategy.

Electric Dewatering Pumps – Clean, Quiet and Cost-Effective

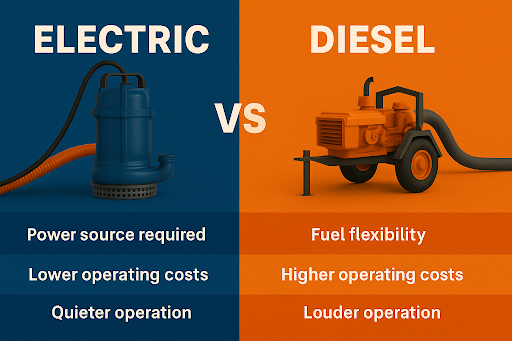

Electric dewatering pumps are often the first choice where a consistent power supply is available. These pumps are energy-efficient, environmentally friendly, and produce minimal noise — ideal for enclosed spaces or densely populated urban areas. Maintenance is simpler and more affordable, and they generally have a longer service life when used appropriately.

Moreover, electric models offer operational cost savings over time, making them a smart investment for sites with reliable electricity. As a leading industrial pump supplier, VEMC provides a wide range of electric pumps tailored to industrial needs.

Diesel Dewatering Pumps – Rugged, Reliable and Ready Anywhere

Diesel dewatering pumps have high pumping capacity and are often used in the high demanding environment, including remote or emergency situations where power is unreliable or absent. Moreover, they excel in removing large volumes of water speedily and efficiently, making them highly demanding for evacuation, construction and other applications needing to control water levels.

Though they require more maintenance and have higher fuel costs, their independence from the grid makes them a go-to choice for flood relief, mining, and infrastructure projects. VEMC, one of the most experienced industrial pump suppliers, ensures high-quality diesel pump solutions across sectors.

Electric dewatering vs diesel dewatering pump

| Feature | Electric Pumps | Diesel Pumps |

| Power Source | Grid electricity | Diesel fuel |

| Best Use Case | Urban sites with stable power | Remote/off-grid locations |

| Maintenance | Low | Moderate to high |

| Noise Levels | Quiet | Noisy |

| Portability | Limited | Highly portable |

| Environmental Impact | Low (no emissions) | Higher (due to fuel combustion) |

Choosing the Right Pump: Things to Consider

To make the right decision, weigh these factors is critical:

- Site accessibility and terrain

- Power supply availability

- Project duration and urgency

- Budget and operational costs

- Environmental compliance

Kirloskar Pumps: Trusted in Both Categories

Whether you need diesel or electric, Kirloskar pumps deliver unmatched quality and durability. As an authorised water pump dealer, VEMC provides expert support, genuine products, and end-to-end installation services. They are among the top water pump dealers in Mumbai for all industrial and municipal pumping needs.

Choosing between electric and diesel dewatering pumps depends on your site conditions, urgency, and access to power. For reliable, expert-backed solutions, trust VEMC, a leading Kirloskar pump dealer and one of the most reputed water pump dealers in Mumbai.

Need help with pump selection? Contact VEMC – your go-to partner for Kirloskar pumps and industrial pump solutions. Reach out today at +91 8976951701, +91 98199 07445, 022 43117133 or email marketing@vemc.co.in for premium dewatering pumps.