In industrial applications, starting the speed and starting motors efficiently is crucial to ensure longevity and optimise performance. For that, two popular options are soft starters and variable frequency drives or VFDs. Both are designed to regulate motor operation but in different ways, offering unique benefits based on the application.

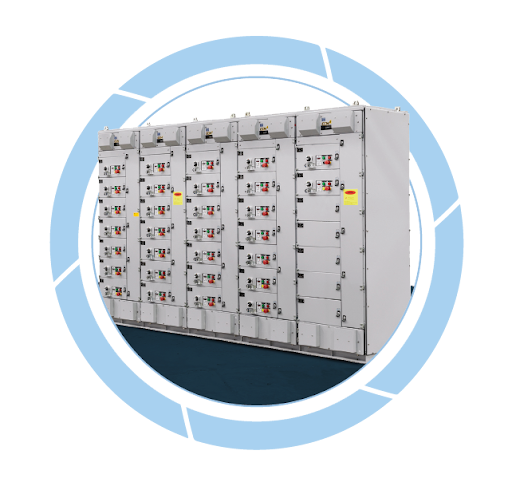

As MCC panel manufacturers, it’s important to choose the right motor control solution based on your needs, whether it’s optimising energy use or ensuring a smooth start-up.

How VFDs and Soft Starters Work

Variable Frequency Drives (VFDs) and soft starters are used to control motors, but their methods of doing so are quite different.

VFD controls the motor’s speed by changing the frequency of the electricity going into it. It enables the motor to run at different speeds, which is useful for the applications that require flexibility, like fans and pumps.

Soft starters, on the other hand, work by gradually increasing the voltage during the motor start-up. However, once the motor achieves full speed, it starts running at a constant pace.

How They Affect Torque and Current Draw

VFDs control both current and torque ensuring a smooth start. It adjusts the frequency and avoids harmful current surges. Significantly, soft starters reduce voltage by limiting the starting current. But they don’t offer the same torque control as VFDs.

Energy Savings in VFDs and Soft Starters

VFDs adjust motor speed to match the load which leads to energy savings. They are ideal for fans, pumps, and compressors.

However, soft starters only reduce energy consumption during startup. Once the motor reaches full speed, it consumes the same energy regardless of load.

Harmonic Distortion: What You Need to Know

Both VFDs and soft starters can cause harmonic distortion which affects the power and quality. VDSs create more harmonics due to frequency changes and require filters. Soft starters produce fewer harmonics, making them simpler for power quality concerns.

For that, MCC panel manufacturers offer solutions to minimise harmonic distortion to ensure stable power for your systems.

Cost and Long-Term Benefits

Soft starters are more affordable as they are simpler and have lower installation costs. Significantly, VFDs are equipped with advanced technology requiring a higher initial cost to purchase. However, they can offer significant savings over the years.

Best Applications for VFDs and Soft Starters

Choosing the right motor control device depends on the type of motor application:

VFDs are best for—

- Pumps (water, chemicals, etc.)

- Fans (air conditioning and ventilation)

- Compressors (for refrigeration and air systems)

Soft starters are commonly used in:

- Conveyors (moving materials)

- Crushers (in mining or construction)

- Constant-speed loads (such as mixers or mills)

Conclusion

VFDs are perfect for energy savings and speed control, while soft starters are great for smooth, cost-effective starts.

At VEMC, we, as trusted MCC panel manufacturers, offer both solutions in our advanced MCC control panels to boost performance and efficiency.

Need expert help? Contact us at +91 8976951701, +91 98199 07445, 022 43436655, 022 43117133 or marketing@vemc.co.in.

Learn more about our MCC control panels here.