Electric motors and pumps work as a single system. While a pump determines hydraulic performance, the motor defines reliability, safety, and operating efficiency. Selecting the right motor enclosure is especially critical when integrating motors with Kirloskar pumps, which are widely used across water supply, industry, infrastructure, and hazardous process applications.

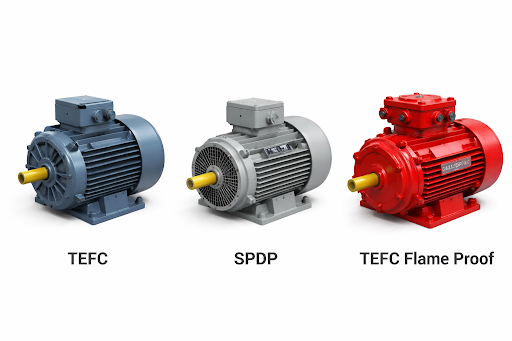

This article compares TEFC, SPDP, and TEFC Flame Proof motors and explains how each can be effectively coupled with Kirloskar pumps for optimal performance.

Understanding Motor Enclosures – Why They Matter

Motor enclosures protect internal components from the surrounding environment and influence:

- Cooling efficiency

- Operational safety

- Service life

- Suitability for application conditions

When paired with high quality Kirloskar pumps, the right motor enclosure ensures stable flow, reduced downtime, and long term system reliability.

Comparison of TEFC, SPDP & TEFC Flame Proof Motors

| Parameter | TEFC Motor | SPDP Motor | TEFC Flame Proof Motor |

| Full Form | Totally Enclosed Fan Cooled | Semi Protected Drip Proof | Totally Enclosed Fan Cooled – Flame Proof |

| Cooling Method | External fan over ribbed body | Natural air circulation | External fan with pressure resistant enclosure |

| Ingress Protection (Typical) | IP55 / IP56 | IP21 / IP23 | IP55 / IP65 |

| Operating Environment | Dusty, humid, outdoor | Clean, dry indoor areas | Hazardous, explosive atmospheres |

| Safety Level | High | Moderate | Very high (explosion containment) |

| Maintenance | Low | Low–moderate | Low but certified maintenance required |

| Cost Factor | Medium | Low | High |

| Typical Applications | Pumps, compressors, conveyors | Fans, machine tools | Refineries, chemical plants, mines |

Integrating Motors with Kirloskar Pumps

Kirloskar pumps are designed for robust performance, standardised mounting, and compatibility with IEC motors, making integration straightforward across all three motor types.

1. TEFC Motors with Kirloskar Pumps

Ideal Pump Applications

- End suction pumps

- Monoblock pumps

- Split case pumps

- Vertical turbine pumps

- Process pumps

Why TEFC + Kirloskar Pumps Work Well

- TEFC motors offer excellent protection against dust and moisture, matching Kirloskar pumps used in industrial, municipal, and infrastructure projects.

- Ribbed housing ensures effective heat dissipation during continuous pump operation.

- Suitable for outdoor installations such as water supply schemes, cooling water circulation, and fire fighting systems.

Typical Use Cases

- Water treatment plants

- HVAC circulation systems

- Industrial process water transfer

- Irrigation pumping stations

Value Delivered:

Long service life, minimal breakdowns, and consistent hydraulic output.

2. SPDP Motors with Kirloskar Pumps

Ideal Pump Applications

- Indoor centrifugal pumps

- Utility water pumps

- Light duty process pumps

Why SPDP + Kirloskar Pumps Are Used

- SPDP motors are cost effective and efficient in clean indoor environments.

- Kirloskar pumps with stable baseplate alignment work well with SPDP motors in controlled conditions.

- Lower enclosure cost reduces overall project CAPEX.

Limitations to Consider

- Not suitable for dusty, wet, or outdoor locations.

- Requires proper ventilation and clean surroundings.

Typical Use Cases

- Pump rooms inside buildings

- Educational institutions

- Commercial complexes

- Machine tool cooling systems

Value Delivered:

Lower initial cost with reliable performance in clean environments.

3. TEFC Flame Proof Motors with Kirloskar Pumps

Ideal Pump Applications

- Chemical process pumps

- Hydrocarbon transfer pumps

- Solvent handling pumps

- Effluent and hazardous fluid pumps

Why Flame Proof Motors Are Critical

- These motors are designed to contain internal explosions, preventing ignition of surrounding flammable gases.

- When coupled with Kirloskar process and API pumps, they ensure regulatory compliance and operational safety.

Certifications & Compliance

- PESO / CMRI / ATEX (as applicable)

- Essential for installations in Zone 1 & Zone 2 hazardous areas.

Typical Use Cases

- Refineries

- Chemical manufacturing units

- Oil & gas terminals

- Pharmaceutical plants

Value Delivered:

Maximum safety, statutory compliance, and risk mitigation.

Key Integration Considerations with Kirloskar Pumps

When selecting a motor for Kirloskar pumps, ensure:

- Power rating (kW/HP) matches pump duty point

- Speed (RPM) aligns with hydraulic design

- Frame size & shaft dimensions comply with IEC standards

- Duty class (S1 continuous) is suitable for pump operation

- Environmental conditions match motor enclosure rating

Kirloskar pumps are designed to accommodate these standards, enabling smooth coupling via flexible or rigid couplings with minimal alignment issues.

Conclusion: Selecting the Right Motor Pump Combination

| Application Condition | Recommended Motor Type |

| Clean, indoor environment | SPDP |

| Industrial / outdoor use | TEFC |

| Hazardous & explosive areas | TEFC Flame Proof |

Pairing the right motor enclosure with Kirloskar pumps ensures:

- Higher system efficiency

- Reduced maintenance cost

- Improved safety

- Longer equipment life

About VEMC

Vijay Engineering & Machinery Company (VEMC) is an authorized channel partner of Kirloskar Brothers Limited, offering end to end support in pump selection, motor integration, installation guidance, and after sales service.

Need help selecting the right motor for your Kirloskar pump?

Our technical team is ready to assist.