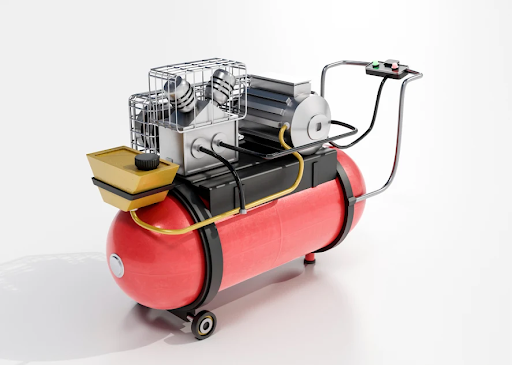

Reciprocating air compressors have served industries reliably for decades. Many plants continue to operate older piston compressors that were installed years ago and still “get the job done.” However, rising energy costs, increasing maintenance issues, and evolving production demands are forcing industries to reassess their compressed air systems.

Upgrading an old reciprocating compressor is not just about replacing equipment—it is about improving efficiency, reliability, air quality, and long-term operating costs.

Before making a decision, here are the key factors every industry should carefully consider.

Understanding When an Upgrade Becomes Necessary

An old reciprocating compressor may still run, but warning signs often indicate it is no longer efficient:

- Frequent breakdowns or unplanned shutdowns

- High electricity consumption

- Excessive noise and vibration

- Declining air pressure or inconsistent output

- Rising maintenance and spare part costs

If your compressor is more than 8–10 years old, chances are that newer technologies can deliver significant operational and financial benefits.

1. Energy Efficiency & Power Consumption

Older compressors typically operate at fixed speeds and often run even when full air demand is not required.

What to Evaluate:

- Motor efficiency class (IE1 / IE2 vs modern IE3 / IE4 motors)

- Load–unload losses

- Specific power consumption (kW per CFM)

Why It Matters:

Compressed air is one of the most expensive utilities in a factory. Newer compressors are designed to:

- Consume less power per unit of air

- Reduce idle power losses

- Operate efficiently across varying load conditions

Upgrading can lead to 15–30% energy savings, depending on usage patterns.

2. Maintenance Costs & Spare Availability

As reciprocating compressors age, maintenance becomes more frequent and expensive.

Key Considerations:

- Rising costs of valves, piston rings, gaskets, and seals

- Longer downtime during overhauls

- Difficulty in sourcing genuine spare parts

Modern compressors are designed with:

- Longer service intervals

- Improved component life

- Easier access for maintenance

Lower maintenance frequency = higher uptime and predictable operating costs.

3. Air Quality Requirements

Today’s industrial processes demand cleaner and drier compressed air than ever before.

Older compressors often struggle with:

- Higher oil carryover

- Moisture contamination

- Inconsistent air quality

Evaluate Your Application:

- Is your air used for painting, packaging, food processing, or instrumentation?

- Are you facing issues with moisture or oil contamination?

Upgrading allows you to:

- Improve air quality standards

- Integrate efficient dryers and filters

- Protect downstream equipment and processes

- Noise, Vibration & Workplace Safety

Older reciprocating compressors are known for:

- High noise levels

- Strong vibrations

- Increased stress on foundations and piping

These factors impact:

- Operator comfort

- Workplace safety

- Compliance with noise regulations

Modern compressor designs offer:

- Quieter operation

- Better vibration isolation

- Improved enclosure and acoustic treatment

This creates a safer and more comfortable working environment.

5. Capacity & Future Air Demand

Many plants expand production over time, but the compressed air system remains unchanged.

Ask These Questions:

- Has your air demand increased since installation?

- Are you running the compressor continuously at high load?

- Do you plan to add new machines or processes?

An upgrade is the right opportunity to:

- Recalculate actual air demand

- Select a compressor with adequate capacity margin

- Avoid overloading or frequent cycling

Correct sizing ensures efficiency, reliability, and future readiness.

6. Technology Shift: Is It Time to Move Beyond Reciprocating?

While reciprocating compressors are suitable for intermittent or low-duty applications, many industries benefit from upgrading to newer technologies.

Consider Alternatives If:

- Your compressor runs continuously

- Air demand is stable or increasing

- Energy costs are a major concern

Options include:

- Energy-efficient reciprocating compressors

- Rotary screw compressors for continuous duty

- VFD-based compressors for variable demand

Choosing the right technology can dramatically improve life cycle cost.

7. Automation, Monitoring & Smart Features

Older compressors lack real-time monitoring and diagnostics.

Modern systems offer:

- Digital controllers

- Remote monitoring

- Alarms and performance tracking

- Predictive maintenance alerts

These features help:

- Prevent unexpected failures

- Optimize compressor usage

- Improve plant-wide energy management

Upgrading supports smart factory and Industry 4.0 initiatives.

8. Installation, Space & Infrastructure Compatibility

Before upgrading, assess:

- Available floor space

- Electrical infrastructure

- Foundation and ventilation requirements

- Integration with existing air receivers and pipelines

A proper site assessment ensures:

- Smooth installation

- Minimal production disruption

- Optimal compressor performance

9. Total Cost of Ownership (TCO) – Not Just Purchase Price

The lowest purchase price does not always mean the lowest cost.

When upgrading, consider:

- Initial equipment cost

- Energy consumption over 10–15 years

- Maintenance and spare parts

- Downtime and production losses

Modern compressors often have a shorter payback period due to energy and maintenance savings.

Conclusion: Upgrade with a Long-Term Perspective

Upgrading an old reciprocating compressor is a strategic investment—not an expense.

A well-planned upgrade can deliver:

- Lower energy bills

- Reduced maintenance and downtime

- Better air quality

- Improved safety and working conditions

- Future-ready compressed air systems

By evaluating efficiency, capacity, technology, and long-term costs, industries can ensure their compressor upgrade delivers maximum value and reliability.