If you’ve ever tried selecting an industrial pump without understanding its performance curve, you’re essentially working blind. A pump performance curve is your roadmap; it tells you exactly how a pump will behave under different operating conditions. For plant engineers and OEMs, reading these curves correctly can mean the difference between smooth operations and costly inefficiencies.

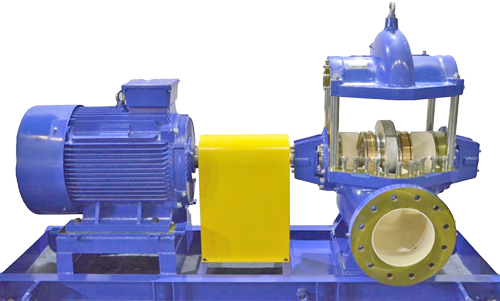

As trusted pump manufacturers and APOEM suppliers, VEMC works closely with clients to simplify this process. Here’s a breakdown of the six most important parameters on a pump curve and why they matter.

1. Flow Rate (Q) – The Pump’s Output

Measured in cubic metres per hour (m³/h) or litres per second (l/s), the flow rate shows how much liquid the pump can move over time. It’s one of the first things you check to ensure the pump meets your process requirements. Too little flow, and your operations slow down; too much, and you waste energy.

2. Head (H) – How High It Can Go

Head is the vertical height the pump can lift water, expressed in metres. Think of it as the pump’s “muscle” against gravity and system resistance. Kirloskar pumps, for example, display a clear head vs. flow curve so you know exactly what to expect for your site conditions.

3. Efficiency (%) – Finding the Sweet Spot

Every pump has a Best Efficiency Point (BEP), the flow rate and head at which it operates most efficiently. Running close to this point reduces energy use, vibration, and wear. Oversizing a pump often means you operate far from the BEP, wasting power and shortening pump life.

4. Power (kW) – The Energy It Needs

The power curve shows the input energy (in kilowatts) your pump requires at different flow rates. Knowing this helps you size your motor correctly and avoid overloads.

5. NPSH – Protecting Against Cavitation

Net Positive Suction Head (NPSH) is crucial for preventing cavitation – those destructive vapour bubbles that damage impellers. Pump curves list NPSH required, so you can compare it against your system’s NPSH available before making a selection.

6. Pump Speed (RPM) – The Performance Shifter

Pump performance changes with speed. A higher RPM can increase head and flow, but may also raise power consumption. Adjustable speed can give you flexibility for varying process needs.

Why It Matters in the Real World

Take a Kirloskar process pump curve: by checking head, flow rate, efficiency, and NPSH together, you can determine the exact model and operating point that keeps your plant running efficiently. This is how you avoid oversizing, underperformance, and unplanned downtime.

If you need a refresher, our pump selection services help OEMs and plant teams diagnose inefficiencies and match pumps to actual system requirements. You can also explore our complete Kirloskar pump range here.

The Takeaway

At VEMC, we’ve been guiding plant engineers and OEMs for decades as trusted pump manufacturers and APOEM suppliers. Whether you need help with selection, diagnostics, or upgrades, we’re here to make your pumping systems work harder for you.

For expert support, reach out to us at +91 8976951701 | +91 98199 07445 | 022 43436655 | 022 43117133 or email us at marketing@vemc.co.in.